6 Min Read

As the current supply chain bottlenecks worldwide have demonstrated, the importance of raw materials inventory management cannot be understated. Without critical raw materials arriving at manufacturing businesses in sufficient quantities or at a specific date, both customers and companies will suffer.

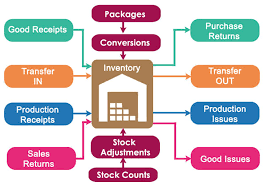

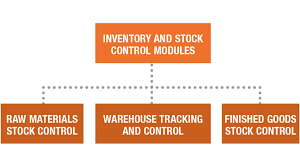

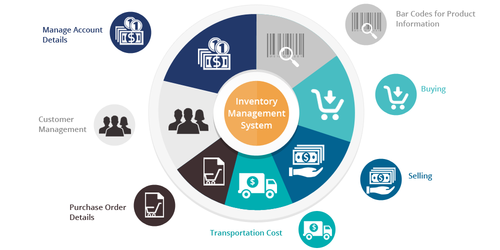

For small manufacturers/small businesses, medium-sized businesses, and large companies, raw materials inventory management encompasses a sizable portion of business operations. For example, raw materials inventory management includes diverse areas such as supply chain management, inventory control, inventory tracking, warehouse management, controlling inventory costs, and ensuring that enough raw material has been procured for the production process.

Business performance will be severely impacted if they do not prioritize every element within raw material inventory management. So, in this article, as well as explaining what is entailed by raw materials inventory management, we will also give some handy tips for how to manage your inventory best!

What is Raw Inventory Management?

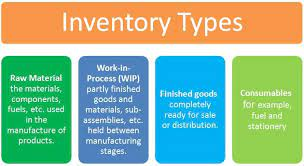

As mentioned, raw material inventory management is primarily concerned with procuring raw materials needed for manufacturing. Businesses must procure two types of raw materials: direct and indirect materials.

Direct materials are the actual raw materials needed for the manufacturing process. For example, for a company making tables, direct materials include the wood, glue, and nails needed to make the table in the first place.

By contrast, indirect materials include all the tools and machinery needed to transform the raw materials into ‘works in progress and finished products/finished goods. Thus, raw material managers must ensure that spare parts and the tools required to service machinery are on hand. Should these spare parts be missing, manufacturers will not be able to convert raw materials into a finished product.

Thus, raw materials inventory management must ensure that many company operations are running smoothly. To this end, material managers are responsible for supply chain management, warehouse management, material procurement, transportation, and more. As these elements are tightly interwoven, any disruption or inefficiency at one point will affect the performance of the other areas.

Smarter Asset Tracking With NFC Tags

Learn more about how NonStop Suite's NFC Asset Tracking Solution can help your Enterprise streamline operations to new heights.

Get A Free Product Tour

What is Raw or Manufacturing Inventory Management Software?

Inventory control software, whether raw or manufacturing inventory software, has become a critical component for managing inventory.

In the past, raw materials inventory management was conducted by pen & paper, and later with spreadsheets and legacy software systems. However, with the advent of advanced management software, inventory software, Enterprise Resource Planning software (ERP software), and manufacturing software, raw material management and manufacturing inventory management has become far more sophisticated.

Essentially, raw material or manufacturing inventory software is a software solution designed for managing the process of raw material inventory management. Thus, manufacturing software can bring considerable benefits to any manufacturing business.

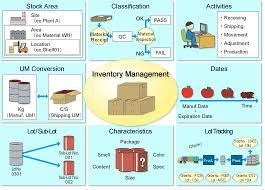

For example, inventory software enables you to track inventory as it moves between multiple locations – such as from your warehouse to your stores. For companies that need to manage multiple warehouses, inventory software is thus critical, as the software enables companies to ascertain inventory levels at various locations and therefore determine where more inventory is required.

Here, the NonStop Suite is a perfect add-on for tracking inventory that needs to be tracked by multiple departments. With Near Field Communication (NFC) technology, such as RFID tags, users in different departments can ensure that the amount of raw material is entirely accurate. Later, we will discuss some of the benefits of accurate date in inventory management.

Additionally, manufacturing inventory software is necessary to help manage the procurement and distribution of raw materials. With this software, management can set reorder points for crucial raw materials. Moreover, they can track the raw material (using serial number tracking) as it moves throughout the supply chain. This, in turn, gives a good indication of lead times for both manufacturers and customers.

Demand forecasting is another powerful feature of manufacturing inventory software. Usually, companies struggle with determining the appropriate stock levels for raw materials. If, for example, companies purchase too much raw material, there is a chance they will never be used (businesses will also incur additional storage costs).

However, with the help of inventory management software, companies can forecast demand using past sales records and seasonal trends. Rather than calculating by hand, this software will automatically calculate the amount of raw materials needed.

With the aid of software, companies will never need to worry about over or understocking again; thus, such software is instrumental in helping companies to maximize their inventory turnover ratio.

When combined with ERP software/ERP systems, companies have complete visibility over their inventory. This means that employees can access the location of inventory items, inventory movements, and inventory status (in other words, if the raw material has been used for manufacturing). Employees can access this data from a mobile device, meaning they can manage inventory items wherever they are!

Techniques for Effective Raw Material Inventory Management

For effective raw material management, there are several techniques that make inventory systems run more smoothly. Let’s look at some of these techniques in more detail!

Avoid Tracking Every Product on Your List

Don’t Rush to Work-in-Progress Management

There are various types of goods/products: raw materials, intermediate goods, and finished goods. Of course, inventory tracking any of these goods takes a significant amount of company time and resources.

Given this reality, companies have to be selective in the goods they account for and track. As it is usually more complicated to track ‘work-in-progress’ goods, you should focus your efforts on only keeping stock of your raw materials and finished products. This entails implementing a software system to help keep track of these goods as they move throughout your supply chains. In addition, only tracking raw materials and finished products will help your company understand total inventory levels and order more raw materials when required.

Constantly Update Safety Stock

Safety stock is an essential element for business operations. Essentially, this type of stock is needed to guard against supply shocks or sudden increases in demand. Notably, the level of safety stock can be readjusted by companies according to changes in production volumes, sales volumes, and changes in supplier lead times.

Closely related to safety inventory are ‘reorder points’ – the point at which new materials are ordered from suppliers. Essentially, your company should establish reorder points for your raw materials before you start dipping into your buffer stock.

Avoid Tracking Every Product on Your List

It is better not to track several materials used in high volumes – like nails, screws, or buttons – as it is too time-consuming for your company.

What is important to track is your high-value raw material. With the NonStop Suite, companies can improve their management of product life cycles with the help of NFC tags. It is possible to make better business decisions with these tags as your company has access to more data. With this data, your company can make essential marketing decisions.

Try Incorporating Industry-standard Metrics into Your Strategies

Ultimately, different businesses will have different strategies to manage their raw materials. However, when deciding which techniques to utilize, it is better to use industry-standard metrics as a guide and select the standards that work for your company.

Benefits of Manufacturing Inventory Software

There are many benefits that your company can derive from using manufacturing inventory software. Let’s discuss a few of these benefits in more depth.

Overcome Potential Challenges Related to the Manufacturing Process

Managing the manufacturing processes for any business within the manufacturing industry can be a challenging endeavor at the best of times. These challenges include problems with suppliers, shipping, warehouse management, and determining adequate buffer stock levels.

With the help of a software solution, companies can overcome these challenges. With features such as assistance with quickly assembling a bill of materials, adding shipping costs onto all purchase orders, financial planning, multi-warehouse management, production planning, and determining production costs, the manufacturing process at your business will be significantly easier!

Effective Planning and Forecasting

Effective planning and demand forecasting are some of the most critical tasks for a company. Before purchasing raw materials for manufacturing, businesses must anticipate customer demand correctly. Without correctly determining customer demand via accurate forecasting, companies will have either too much or too little stock for the upcoming season.

Effective planning requires cooperation between different company departments. With the help of the NonStop Suite, this cooperation is made seamless as various departments can work on a centralized data set. When all the required input is given, your company can then make informed decisions regarding demand forecasting.

Data-driven Management

Your company needs enough high-quality data in order to have the correct amount of stock for any sales season. This data should cover past sales seasons and current stock levels to see when your company needs to reorder raw materials from suppliers. When combined with inventory tracking, software solutions will automatically update current stock numbers in real-time; of course, companies cannot achieve this if they still track inventory via pen & paper or spreadsheets.

Additionally, data-driven management facilitates supply chain management methods such as the ‘vendor-managed inventory’ method. This inventory method relies on the buyers of raw materials to share their data with their suppliers; in turn, the suppliers then decide how much stock to reserve for the buyer. As a result, companies can significantly reduce lead times with this method as stock is already set aside by the supplier. Downstream effects of this include faster manufacturing times and increased customer satisfaction.

Track Costs

Even without using manufacturing software, it is possible to calculate the direct costs of purchasing raw materials. However, it will be difficult for your business to calculate additional costs that are prone to changing suddenly without utilizing enterprise resource planning software. These include labor costs, shipping costs, and other overhead costs. Therefore, tracking these somewhat more challenging costs with ERP software becomes more straightforward.

Wrapping Up!

Determining how you should implement a raw material inventory management system (with the aid of a software solution) can be challenging. This is why you should consult with the NonStop Group, a group with a wealth of experience in helping clients in the manufacturing, logistics, and transportation industry. The NonStop Group can help replace paper-based forms with mobile inventory management and introduce NFC tags to ensure you have total visibility of your inventory. Should you want these results and more, contact the NonStop Group today!