10 Min Read

Asset Tracking

It is vital for any asset-intensive organization to effectively track and monitor high-value assets throughout their entire life cycle, from procurement to end of life.

By implementing asset tracking solutions that are suited to your specific business needs, asset-heavy organizations can improve asset visibility and asset management, efficiency and productivity, and customer satisfaction, while reducing costs and increasing profitability.

It is essential that time is spent up-front to determine the specific types of asset tags and software solutions that will deliver optimal business results.

Why would an organization need to tag an asset?

Depending on the type of business, organizations typically tag assets to:

- Monitor inventory levels.

- Track supply chain activities.

- Monitor asset location in real time across multiple sites.

- Prevent assets from being lost, misplaced or stolen.

- Monitor the condition of an asset as part of an asset management program.

What types of assets are typically tagged?

Organizations typically tag fixed and mobile high-value and revenue-critical assets to track and monitor an asset’s location, condition, maintenance activities and history.

Where does asset tag information go?

Asset tags contain important asset-specific information such as name/ID, condition, value, history and location. This information is read by means of a reader/scanner and is communicated to an asset tracking software system where the information is stored, evaluated, and analyzed to make informed decisions and take the appropriate actions.

What can asset tagging software help improve?

By automating the asset tracking process and integrating it with a sophisticated asset tracking software system, major benefits can be realized for the organisation:

- Eliminate human intervention, thus reducing the risk of error and amount of manual labor required to perform asset tracking and monitoring.

- Collect real-time data.

- Track multiple assets simultaneously.

- Improve asset visibility.

- Identify obsolete assets.

- Reduce maintenance activities and costs.

- Enable effective decision-making.

- Enhance inventory management.

- Improved compliance with regulatory requirements.

- Improved efficiency, accuracy and productivity.

What is an RFID tag?

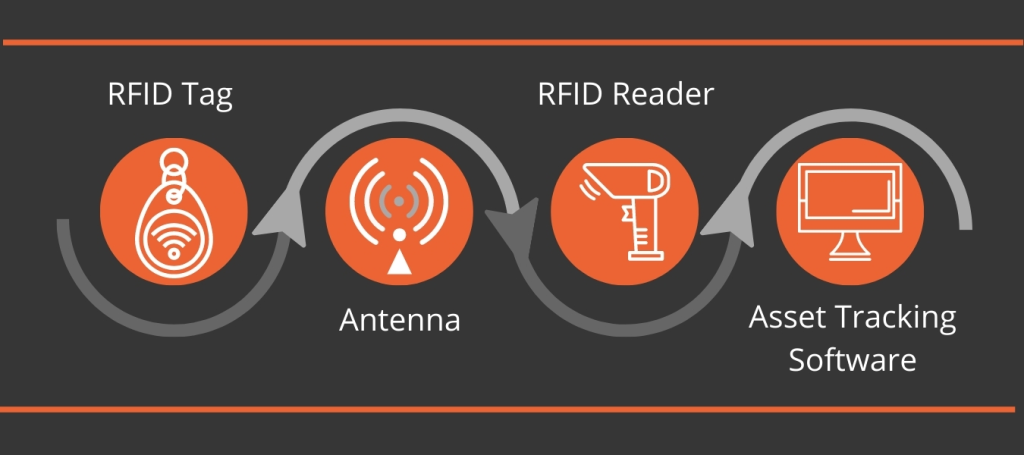

A radio frequency identification (RFID) tag refers to technology where digital data is encoded in a tag, such as equipment specific name/ID, value, location and condition. The tag is attached to a specific asset, and the information is captured by means of a reader via radio waves. The information is transmitted to an asset tracking software system where it is stored, analyzed, and transformed into actionable intelligence.

An effective RFID asset tracking system comprises five key technological elements.

1. RFID tag

Equipment-specific digital data is stored on the RFID tag, and is attached to the asset to be tracked and monitored. Three types of asset tags can be utilized, namely active, passive and semi-passive RFID tags.

Active RFID tags

These tags are generally larger and more expensive than passive RFID tags. They offer longer read ranges of up to 150m, but active tags typically have a more limited lifespan than passive tags. They are battery powered and continuously transmit a signal.

Active tags are often used in harsher environments. They are typically used to track assets like vehicles and cargo containers.

Passive RFID tags

Passive RFID tags are typically smaller and less expensive than active tags, but their reading ranges are shorter. They, however, have a longer lifespan than active tags.

Passive tags have no internal power source, and are powered by the radio frequency energy transmitted from RFID readers/antennas. The signal sent by the reader and antenna is used to power the tag.

These tags are typically used for inventory and supply chain management.

Semi-passive RFID tags

Semi-passive RFID tags have and internal power source, but has a low signal range compared to active tags. These tags are used in a close distance from the reader. They are typically used for environment and condition monitoring.

2. Antenna

The signal of a nearby RFID tag is identified by the antenna. The antenna receives the stored data from the tag and transmits the data to an RFID reader.

3. RFID reader

An RFID reader, connected wirelessly to the antenna, receives data that is stored on the tag.

4. Asset tracking software and database

The RFID reader transmits data to the asset tracking software where it is stored, analyzed and transformed to business intelligence that is used to make informed decisions and take appropriate actions.

5. Levels of frequency

Frequency output impacts the cost, size, and communication quality between tags and readers. Therefore, it is important to consider which frequency output is best suited to your needs and circumstances.

Low frequency

Low frequency ranges between 125-134 kHz, and has a long wavelength. Signals can penetrate solid materials and high water content. Typically, the signal range is limited up to 10cm.

High frequency

High frequency operates at 13.65 MHz and can penetrate metals and medium-to-high water levels. The signal range is typically limited up to 1 meter.

Ultra-high frequency

Ultra-high frequency operates at 860-960 MHz and has shorter wavelengths, which typically can’t pass through metal and water. It has a great signal range of up to 150 meters.

The benefits of an RFID tracking system

- With RFID, multiple tags can be read simultaneously without having to have direct line of sight between the tags and the scanner.

- Maintenance information can be stored on the asset itself, enabling more effective asset life cycle management.

- RFID tags can be integrated with GPS technology to provide asset condition data.

- Improved inventory management.

- Improved asset security through real-time tracking, to prevent assets from being lost or stolen.

- Improved efficiency and productivity.

- Improved asset management.

- Improved cost management.

Why would a paper tag be useful?

Paper tags can be useful in specific applications such as inventory management in warehouses and stock rooms. As paper tag tracking is less expensive to implement than other types of asset tracking technology, it is often used in smaller companies with a large number of assets, as well as in organizations with a limited budget.

A major benefit of paper tags is that they can be used on most materials and has a high level of data tracking accuracy.

Between paper tags and RFID tags which is more commonly used?

It is important to implement a fit-for-purpose asset tracking system that takes your organization’s needs, circumstances and budget into account to deliver optimal business benefits.

Your asset tracking system could potentially include a mix of RFID and paper tags. Let’s have a closer look at the advantages, drawbacks and typical applications of each.

RFID tags: Advantages

- Efficiency: Can scan multiple barcodes simultaneously without having direct line of sight between the scanner and the tag.

- Durability: Can handle exposure to harsh conditions.

- Substantial asset tracking range of up to 150 meters.

- High level of asset tracking accuracy.

- Once the system is set up, it requires little intervention.

- Can contain a large amount of asset-specific data.

- High level of data security with password and encryption functionalities.

- Significant return on investment (ROI).

RFID tags: Drawbacks

- RFID technology can be restrictive in metals and sometimes in water as well.

- RFID technology is more expensive than paper tags and scanners.

- More time-consuming to implement.

RFID tags: Drawbacks

- Low frequency RFID tags are often used in animal tracking and access control.

- High frequency RFID tags are typically used where items need to be checked in and out, for example in libraries, and with medical supplies and items.

- Ultra-high frequency (UHF) tags are typically used for shipping and receiving, end-to-end manufacturing, and industrial asset management.

- Supply chain management for real-time updates regarding stock levels, location and condition as well as historical sales information.

Paper tags: Advantages

- Barcodes can be used on almost all materials – not restrictive.

- High level of asset tracking accuracy.

- Less expensive than RFID technology.

Paper tags: Drawbacks

- Must have direct line of sight between the scanner and the tag and has a limited asset tracking distance.

- Inefficient: Can only scan one barcode at a time. Time-consuming and labor-intensive.

- Paper tags are not very durable and must be reprinted from time to time.

- Can only store a limited amount of data.

- Reduced data security as barcodes can be duplicated.

Paper tags: Typical applications

- Inventory management in stock room and warehouses.

- Small businesses with a large number of assets.

Final thoughts

Effective asset tracking is vital for any asset-intensive organization. It will improve asset visibility and asset management, efficiency and productivity, and customer satisfaction, while reducing costs and increasing revenue.

It is essential to determine the business requirements, environmental circumstances and specific applications when developing your asset tracking system. It should be customized for your business specifically and could contain various types of asset tags and technology. It is important that the system is supported by sophisticated asset tracking software where information can be stored, analyzed, and turned into intelligence that will inform business decisions and actions to be taken.

Therefore, it is worth the time, effort and upfront investment required to procure the necessary asset tracking tools, technology and software systems that will deliver significant business results.