6 Min Read

The Covid-19 pandemic has perfectly illustrated the difficulties of supply chain management, materials management, logistics, and inventory management/inventory control. Yet, no matter how complex material management may be, securing these materials is vital for businesses to continue delivering quality services to their customers.

Additionally, materials management and supply chain management are critical for current business operations and supporting a future scale-up.

What exactly is materials management? Fundamentally, materials management is concerned with procuring raw materials, intermediate components, and ensuring that a finished product reaches the end-users.

Due to the scope of materials management, it encompasses other activities such as supply chain management, logistics, inventory control, and even securing spare parts for their business! We will discuss the scope of material management in more detail below!

Planning for the procurement of raw materials or intermediate components might seem like a daunting challenge. Indeed, even businesses with effective material management and procurement strategies might not be utilizing it to maximum potential.

For a company to see significant cost savings, an improvement in their planning process, and the services they offer to their customers, they should consult a material management service

What are Material Management Services?

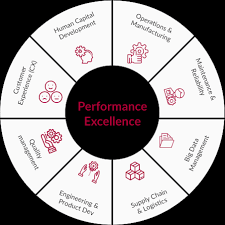

Simply put, material management services help companies with devising and updating their material management strategies. Should a company consult with a material management service, the first thing they can expect is a complete and holistic breakdown of their business operations.

This means that materials management and procurement are not viewed in isolation. Instead, materials management will be considered a series of interlocking parts, with each piece impacting the company’s functioning.

Thus, not only can a material management service help create and plan a strategy for materials management and procurement, but they can also help with updating and revising every aspect of your approach to materials management.

For example, should your company’s supply chain and logistics arms be underperforming, material management services can improve the efficiency of both elements.

Or, should your company be struggling to find raw materials or spare parts at a reasonable price, material management services assist by helping to locate new vendors and suppliers for your company.

Crucially, materials management services help your company gather and interpret data on procurement, sales, distribution, inventory, and storage. With this data collected and analyzed, your company can make better business decisions that can improve the quality of your services.

As mentioned, material management services focus on the big picture. Therefore, should your company opt to consult with material management services, you can be sure that your entire material management strategy will be revamped.

This will result in your company increasing sales, seeing significant cost savings, reduced waste, and happier customers eager to use your services again!

Smarter Asset Tracking With NFC Tags

Learn more about how NonStop Suite's NFC Asset Tracking Solution can help your Enterprise streamline operations to new heights.

Get A Free Product Tour

Objectives of Material Management

Material management focuses on the entire product life cycle, like material management services.

This means that material management begins when raw materials needed for production are purchased until customers receive their final product. Any processes between these two points are also the responsibility of the materials’ manager.

As materials management is concerned with purchasing and the procurement of materials, material managers must ensure that their supply chain is secure to ensure the constant availability of materials. If the supply chain linking businesses and suppliers is not operational, business operations will struggle to continue.

Materials management is also concerned with inventory control and inventory management. Once the purchasing of raw material is complete, material managers move to the next stage of planning: inspecting the material quality and preparing the inventory for distribution and storage.

Material distribution and storage are essential processes closely related to the amount of stock ordered. Essentially, the amount of stock distributed and held in storage must reflect an organisation’s current material or production requirements.

Should businesses order too much inventory, they will pay unnecessary storage costs. Additionally, ordering excess stock will harm a company’s bottom line. For this reason, material management must use data from previous sales to support the company when they purchase new materials.

Finally, materials management must also ensure that customers and clients are satisfied with your services. Should clients receive quality products quickly, they will be eager to use your services in the future!

Types of Material Management Services

Material management services can help companies in a significant number of industries! For example, scientific, manufacturing, logistics, and even retail businesses, can all find material management services ready to help them!

Of course, the particular services and software solutions offered by material management services will differ by industry.

5 Ways It Can Benefit You

Whether you are consulting with material management services or devising your strategy for inventory management, here are some benefits of having a robust system to manage materials. Of course, your company must support this strategy with Enterprise Resource Planning (ERP) software solutions for maximum benefit.

Evaluation of Materials

With the assistance of software, purchasing decisions become much more straightforward! Material management software can calculate the overall costs of acquiring the material for sale. These costs include direct material costs, freight costs, and import duties.

With this data at your disposal, your business can make prudent and better-purchasing decisions!

Efficient Bin Management

Among the most important reasons you need software to support business operations is efficiently managing your inventory bins. Businesses can store incoming inventory in the preferred bins in the rack system. Then, when the order fulfilment process begins, inventory and stock can be easily located from the bins. Additionally, your business will receive automated alerts indicating when inventory levels become low.

Efficiently managing your bin is important for two other reasons. First, for inventory control and management, an organized inventory bin will reduce storage costs as businesses know the amount of current stock.

Secondly, managing your inventory bin efficiently results in a faster order-execution process. This benefits your customers and clients immensely as they will receive their products faster. As a result, customers and clients have an excellent reason to use your services again.

Lot/Serial No. Traceability

ERP software can help track inventory, spare parts, and even machinery needed for production. Each unit will have a lot or serial number, meaning businesses can trace these units as they move from purchase to the final location.

Additionally, a secure record of each transaction can be saved and retrieved for sales and returns. This transaction history is also vital for locating the source of problems with inventory or stock.

Product Life Cycle Management

As mentioned earlier, purchasing new stock is vital for business operations. However, purchasing new stock without analyzing whether the products will sell can negatively affect your bottom line. Essentially, material managers should examine which products are in demand and which are no longer desired by customers.

ERP software can assist with demand forecasting using sales records from previous seasons. This is important to prevent purchasing too much stock/too little stock, which can harm your company’s bottom line.

Inventory Management

Inventory management is closely related to product life cycle management, which focuses on the procurement and replenishment of new stock. With ERP software, you can set differentiated re-order points for individual products. ERP software also provides a range of replenishment planning strategies – such as economic order quantity – that further streamline production and procurement processes.

Effortless Scheduling

With the aid of ERP software, planning the procurement of materials and subsequent production schedules has never been easier! In addition, as the entire ERP system is integrated, and because all employees have mobile access to it, controlling the production schedule and updating employees of significant changes is a simple process!

Additionally, should machinery need to be serviced or spare parts need to be installed, this maintenance work can be scheduled with the aid of software quickly and with the least hassle to the production process.

Multi-Location Inventory

As your business or company expands, so will your office and warehouse locations. When office, manufacturing, and warehousing units are in different locations or sites, coordination between employees can become a bit tricky. With the aid of ERP software, however, these coordination problems melt away.

ERP enables you to track progress in manufacturing units from your office; additionally, as inventory is being moved between different locations, inventory levels and details will be updated in real-time to reflect these changes.

Why Do You Need a Material Management Service For Your Business?

Earlier, we discussed why consulting with material management services is vital for your company. With their assistance, not only can they help interpret relevant data, but they completely revolutionize how you conduct material management.

One way that your company’s materials management system can be revolutionized with the help of material management services is by introducing ERP software. But which material management service should you consult?

Wrapping Up!

One consulting group that your company should consider speaking to is the NonStop Group.

The NonStop Group has a rich history of helping clients in the oil & gas, logistics, and manufacturing industries. They have assisted their clients with introducing ERP software solutions, from which they have benefitted immensely. For example, after the NonStop Group helped their clients in the oil & gas industry, they had complete control and visibility of their inventory; paper forms also became a thing of the past, thereby streamlining material management further.

If you want these results and more for your company, contact the NonStop Group today!