6 Min Read

Asking most people what they remember about the year 2020 would see a familiar answer: the spread of the COVID-19 pandemic and the world’s response to it. Yet, another event that (briefly) caught the world’s attention was the explosion at the port of Beirut in August 2020. Eventually, the explosion was classed as an ‘industrial accident/disaster’ due to ammonium nitrate being the cause of the blast.

Unfortunately, the list of disasters involving hazardous chemicals is quite long. To safely handle dangerous chemicals and prevent catastrophic incidents (like the Beirut explosion), various industries that use highly hazardous chemicals must ensure that they are handled, stored, transported, manufactured, and properly controlled under conditions and operating procedures that we recognize as current best practice.

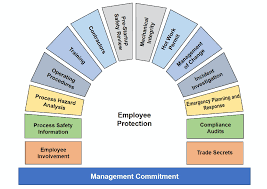

Enter process safety management (PSM), which is essential for maintaining safe and healthy workplaces and ensuring employee, environmental, and communal safety. Process safety management is a comprehensive set of guidelines to which all companies handling hazardous materials must adhere. Let’s now discuss what makes process safety management a complete and holistic set of guidelines.

Process Safety Management: An Analytical Approach to Control the Hazards

Process safety management is often described as an ‘analytical tool’ that companies use to prevent major disasters and the releases of toxic reactive chemicals and ensure chemical stability. As we just mentioned, the consequences of not managing highly hazardous chemicals correctly is potentially fatal. As an analytical tool, a PSM program establishes what safety information is required, the safety procedures to be implemented, and the design principles that must be followed to handle hazardous chemicals. Should all of these principles and other elements be followed, companies will be able to prevent fires, explosions, the accidental mixing of chemicals, and the release of chemicals.

Additionally, a PSM program combines management frameworks, technology platforms, and specific procedures (such as organizational and operational procedures, safety procedures, management practices, and emergency procedures). Again, the goal of this blended program is for the safe handling of highly hazardous chemicals.

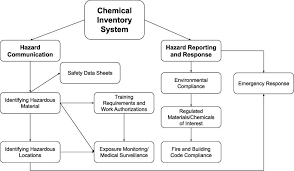

A key feature of chemical inventory software is that this software enables the centralization of data/databases; in effect, a single database is created. Quick and easy access to centralized data is essential when a laboratory (or even multiple laboratories and factories across multiple locations) handles chemicals or manages their chemical inventories. One such benefit (more benefits will be discussed below) of this software is that safety data sheets can be accessed by authorized users quickly. This, in turn, increases safety for employees as they can view hazard definitions and precaution codes for chemicals, and have essential information on chemical storage and chemical disposal. Crucially, the centralization and easy-access of chemical safety information enables this information to be easily shared with emergency responders. Thus, in the event of chemical spillage or any other emergency, responders will have the necessary information on-hand.

However, improving the safety of employees and consumers through the access of essential safety information is only one task chemical and risk management software. Typically, these solutions also support an entire chemical management system. Let’s discuss what is meant by a chemical management system in more detail and how cloud-based solutions help them.

Smarter Asset Tracking With NFC Tags

Learn more about how NonStop Suite's NFC Asset Tracking Solution can help your Enterprise streamline operations to new heights.

Get A Free Product Tour

OSHA Standards for PSM

In 1992, the U.S. Occupational Safety and Health Administration (OSHA) devised 14 elements of process safety management for companies that handle highly hazardous chemicals. OSHA’s process safety management serves as legally binding regulatory requirements for companies that handle hazardous materials and substances. The OSHA PSM standards, of course, are not the only process safety standards. However, they constitute important and legally binding PSM requirements which have risen the overall prominence of PSM. We will discuss all 14 OSHA PSM standards below.

All 14 elements of the OSHA PSM standard must be adhered to. In fact, should companies neglect just a few of the OSHA’s process safety management standards, overall plant and employee safety are compromised. In essence, all 14 of the OSHA’s process safety management standards are dependent on the individual strength of each principle; thus, if one principle is weak, it affects the integrity of the others.

Difference Between Process Safety Management (PSM) and Occupational Safety Management (OSM)

There are essential differences between occupational safety/occupational health policies and process safety management policies. The difference between occupational safety and process safety management is one of scale.

OSM attempts to prevent individual-level or small-scale accidents and disasters, such as ensuring employees are not subject to dangerous situations without safety information and procedures (for example, ensuring that someone does not fall during work). Over the past two years, the advent of COVID-19 has seen an increase in the number of occupational safety measures, including mask wearing for employers/employees, temperature checks, and sanitizing.

By contrast, process safety management is concerned with preventing and managing large-scale disasters. Thus, process safety management attempts to manage risk involving the unexpected releases of toxic chemicals, explosive chemicals, and explosion hazards. OSM will only see small-scale interventions, while process safety management will see fewer interventions but are larger than OSM measures.

Significance of Process Safety Management

As an analytical tool, process safety management encompasses a wide range of technological, managerial, technical, operational, and audit procedures designed to prevent the accidental release of highly hazardous chemicals.

While catastrophic incidents will still occur in the future, the significance of process safety management cannot be understated. A process safety management system is not just essential for employee and contractor health but crucial for the continuation of normal operations within various industries. PSM is also needed to mitigate risks associated with the handling of hazardous chemicals.

Without a robust process safety management system, the handling of hazardous substances (which are essential for the functioning of the global economy) would be compromised. This brings us to the 14 elements of process safety management.

14 Components of PSM

We can now discuss OSHA’s process safety management (PSM) principles. As mentioned, OSHA PSM has 14 elements. To ensure the best results, all 14 elements must be adhered to, as neglecting one principle compromises the integrity of the other principles (and, by extension, overall workplace safety).

Process safety information

Process safety information is considered to be the backbone of any PSM system. Without process safety information, conducting a process hazard analysis is impossible.

Process safety information is a set of written safety information that will help employers and employees understand the hazards they face. Without this information, employees will not be able to know how to use hazardous chemicals or when emergency planning should come into effect. Again, employers are legally obliged to provide safety information to employees as per OSHA.

The information provided by employers will include specific information about the chemicals they are using – such as exposure limits, the hazardous effects of the materials being used, toxicity, reactivity data, and data about thermal stability. Additionally, employers must have information on the upper and lower limits of the equipment used at the plant. For example, employees must know the pressure, flow, and temperature limits to of assets used to process chemicals to ensure continued safety.

Process hazard analysis

Employers and employees can conduct a process hazard analysis of all the chemicals and substances used with process safety information. Thus, all hazardous substances must be identified, evaluated, and controlled when in use. For example, a process hazard analysis would be conducted for flammable liquids and gases at an oil refinery. Once these hazards are identified, employers will provide employees with a checklist containing the details of this analysis.

Operating procedure

Following the first two stages, employers must execute and implement written operating procedures (which are recognized as best practices) during production processes and industrial processes. Operating procedures include adhering to safety features, operating limits, and the correct handling of process chemicals and critical process equipment.

Employee participation

Employee participation is required in the development of process hazard analysis. Additionally, employees must have full access to written procedures on safety management, chemical management, and equipment management.

PSM training

Employee participation does not end here! Process safety entails training employees to handle hazardous chemicals and respond to emergencies. This is critical to the safety of everyone at an industrial plant. As per OSHA guidelines, a refresher course in PSM training must be offered every three years.

Contractor training

Contract employers are responsible for ensuring that their employees have been trained correctly, are aware of hazardous materials, and know how to respond in an emergency. It is only with this information that contractors can perform their jobs correctly.

Pre-startup safety review

New and modified facilities must be subject to a pre-startup safety review before operations begin. During this pre-startup safety review, facilities are inspected to see that construction has followed good engineering practices, that all critical equipment and operating systems have been installed correctly. Additionally, the review must ensure that safety procedures, operation procedures, and emergency procedures have been firmly established.

Mechanical integrity

Critical process equipment – such as piping systems, ventilation systems, pressure vessels, and shutdown systems must be operated according to the written operating procedures that the company has developed. These systems will require periodic inspections to ensure that all process equipment is in good working condition to ensure continued mechanical integrity.

Hot work permit

A hot work permit must be issued to employees or contractors who perform high-temperature work before such work begins. The permit will verify where the hot work will take, how long it will take, and that fire prevention requirements have been met.

Management of change process

Written procedures are required to manage changes that pertain to process chemicals, operating procedures, equipment, and technology. Additionally, when changes are proposed, the following considerations must be addressed:

How the proposed change will impact employee safety.

What the technical basis is for a proposed change.

How long it will take to implement.

How a proposed change would modify current operating procedures.

Before these changes take effect, employers must inform their employees about them.

Incident and accident investigation

Any potential incidents that could lead to a major disaster must be investigated within the first 48 hours. Once this report has been completed, OSHA stipulates that the report must be kept on file for five years.

Emergency planning and response

Process safety management systems must include emergency planning and response. Thus, employees must be trained to implement emergency procedures. In addition, should highly hazardous chemicals need to be released, the entire plant must know how to implement this emergency procedure.

Safety compliance audits

Employers must conduct safety compliance audits every three years to document and confirm that current practices are being adhered to. Compliance audits should also note deficiencies and the corrections taken to address them. Employers must keep the two previous audits on file for OSHA inspectors.

Trade secret status

Employers must provide thorough documentation of the chemicals and processes used to ensure employee safety. This documentation must be provided regardless of trade secret status. However, employers can request employees enter confidentiality agreements to protect trade secrets.

How to Execute Process Safety Management Perfectly into Your Organization

If your organization is unsure how to implement and execute a process safety management program, a good place to start is to consult experts and contractors who specialize in the U.S. Occupational Safety and Health Administration PSM guidelines. Thus, should your organization require training that meets OSHA guidelines, or require help in establishing emergency protocols, be sure to speak to a reliable third-party source today!

We mentioned earlier that periodic inspections are essential to the safety management process. Should your company require a team of inspectors or a maintenance team, consulting with the NonStop Group is a must! The Non-Stop Group has experience in assisting clients in the oil, gas, and manufacturing industries. When the NonStop Group helped their clients in the oil & gas industry, operational accidents were reduced by 76%, and equipment downtime was reduced by 22%. If your company needs results like these, be sure to contact the NonStop Group today!

Additionally, employee safety also increased markedly due to the ease of inventory management. The NonStop Group is also fully compliant with regulations, meaning that your organization can quickly generate audit-ready reports. Should you want these results for your organization, be sure to contact the NonStop Group today!

Advantages of Implementing Process Safety Management Program

There are two main advantages of implementing a process safety management program from a business perspective: risk reduction/mitigation and creating sustained value. Process safety is essential for preventing injury to employees and the surrounding community and guards against the risk of a catastrophic incident (which can cost significant money for a company). Additionally, PSM boosts productivity and produces valuable products on time. In the absence of safety management processes and other guidelines, normal business activity would be impossible, impeding long-term shareholder value.

We mentioned earlier that periodic inspections are essential to the safety management process. Should your company require a team of inspectors or a maintenance team, consulting with the NonStop Group is a must! The Non-Stop Group has experience in assisting clients in the oil, gas, and manufacturing industries. When the NonStop Group helped their clients in the oil & gas industry, operational accidents were reduced by 76%, and equipment downtime was reduced by 22%. If your company needs results like these, be sure to contact the NonStop Group today!

Additionally, employee safety also increased markedly due to the ease of inventory management. The NonStop Group is also fully compliant with regulations, meaning that your organization can quickly generate audit-ready reports. Should you want these results for your organization, be sure to contact the NonStop Group today!