6 Min Read

Quality assurance and compliance is an ongoing and seemingly never-ending battle for many manufacturers. As the number of regulations increases, so too does the intensity of compliance monitoring. As frustrating as these regulatory requirements and compliance monitoring may be, they are both essential for the safety of customers and the overall quality of the products produced. Therefore, a better way to understand the importance of quality processes and compliance regulations is to imagine a scenario where they are absent. Without quality systems and quality control measures in place at businesses, customers would have no guarantees of the quality of the products they receive.

Additionally, the absence of compliance systems is arguably more significant. As we shall shortly explain, ensuring compliance with existing regulations is non-optional; businesses are obligated to follow compliance regulations if they wish to trade and operate their business in the first place. Thus, non-compliance with regulations can result in business operations being suspended (or not even beginning).

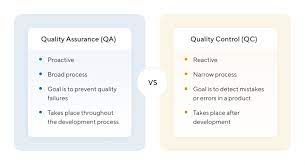

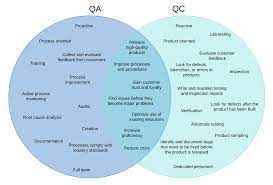

While quality assurance and compliance are often treated and used interchangeably, there is a vital difference between these two terms. We will now discuss these differences. After explaining these differences, we will explain how quality management systems can benefit and encourage quality assurance and compliance at your business.

What is Quality Assurance?

If compliance monitoring is a compulsory and non-optional set of activities that businesses must comply with, quality assurance processes are a set of non-obligatory programs. However, implementing and following quality assurance programs is still essential to overall quality control at any organization.

Quality assurance, therefore, has a different focus than compliance monitoring. Whereas compliance monitoring is focused on meeting necessary regulations, quality assurance focuses on the quality of products produced at your organization.

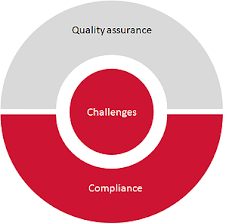

A quality system is, therefore, very different from compliance systems. Essentially, a quality system focuses on the continuous improvement of products at every stage of the product life cycle (such as the design and manufacturing stages). Implementing compliance alone is no longer enough for many businesses to succeed. Thus, for companies to continuously increase the quality of their products (and therefore boost customer satisfaction and customer retention), businesses need to implement both quality assurance and compliance. The companies that succeed best are those that implement a robust quality assurance and compliance program.

As we now see, implementing quality assurance at your business will also increase productivity and decrease costs and material wastage, thereby demonstrating the benefits that quality management delivers to your business.

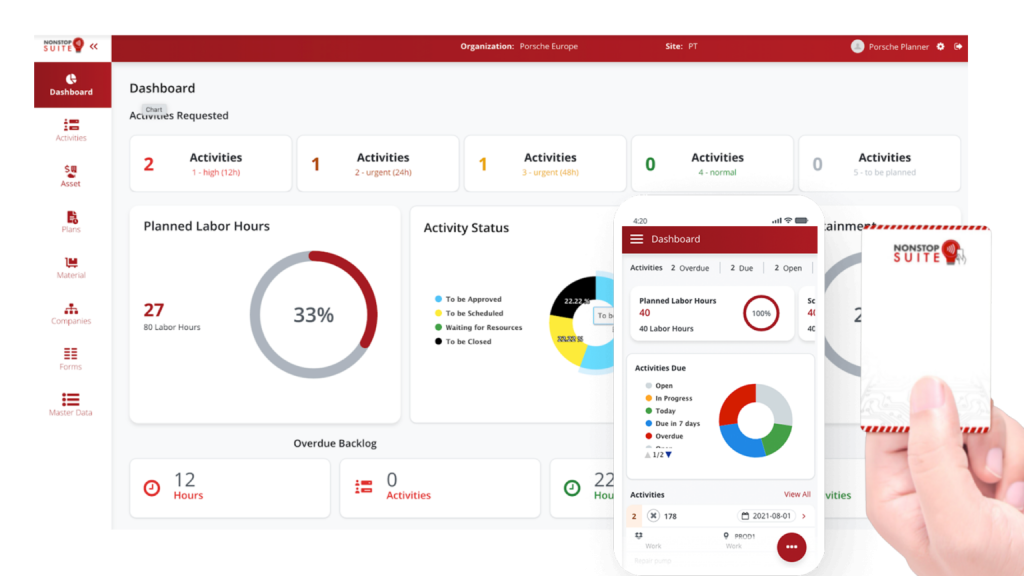

Smarter Asset Tracking With NFC Tags

Learn more about how NonStop Suite's NFC Asset Tracking Solution can help your Enterprise streamline operations to new heights.

Get A Free Product Tour

How Can You Implement Quality Assurance In Your Business?

For quality assurance at your company to be successful, a ‘culture’ of quality at the business must be created first. Thus, there should be close cooperation between quality leaders and the management team in creating a culture of quality assurance. Fundamentally, a culture of quality assurance will see employees at every stage of the product life cycle invested in improving the quality of products for their customers.

Other methods of implementing quality assurance at your company include conducting observations, tests, and assessments on manufactured products. Over time, these will result in a continuous improvement of the products manufactured for your customers. Importantly, the quality assurance feature of testing and comparison is also an essential feature of quality compliance, as we shall see shortly.

Organizations can devote quality control systems and processes to any stage of the product life cycle. For example, when receiving materials from suppliers, quality inspectors can inspect them to determine and evaluate their quality. Should the quality of the material be poor and therefore affect the ability of a business to produce quality goods for its customers, organizations can change their suppliers to improve the quality of their products.

Additionally, when implementing quality management systems, organizations should focus on identifying and monitoring the objectives, challenges, and mistakes made during the production cycle at every stage of the product life cycle. When challenges and mistakes are identified, it is possible to improve the production process and performance in the future. These improvements could include the creation of training programs for employees. With such changes, companies are sure to see an improvement in the service they offer clients.

The benefits of implementing quality assurance programs at your company are manifold. For a start, companies implementing quality assurance can see a reduction in overall cost. In addition, when quality assurance is prioritized at every stage, it is easier to understand how the overall product design might improve; a vital offshoot of this is that the efficiency of production processes and procedures will improve.

Secondly, customer satisfaction will improve immensely if companies focus on implementing quality assurance processes. Should a business only be interested in implementing compliance measures, there is a high possibility that the quality of the product being produced will not be sufficient.

This is especially so compared to businesses that prize quality management and focus on teaching a culture of quality assurance amongst their employees. Of course, consumers are likely to gravitate towards a company with better quality products. To produce these products, only a combination of quality assurance and compliance processes and programs will do.

What is Compliance?

Unlike quality assurance, which is only optional and non-obligatory, regulatory compliance is compulsory and must be followed by any business wishing to produce goods and services.

Essentially, compliance is best thought of as a set of comprehensive regulations and rules implemented by companies. There are several reasons why compliance must be implemented and followed by organizations.

For a start, compliance is necessary for consumers to have confidence in the companies they purchase goods from. This is especially so in the food industry, beverage industry, and healthcare industry. When comprehensive regulations are implemented and followed in these industries, the safety of customers purchasing goods and services certainly improves. Closely related to this reason is the need to manage customer expectations. Simply put, assuring customers that your company is following compliance regulations will go a long way in getting clients to use the services your business offers.

Like quality management, there are several ways that any business can ensure regulatory compliance is being implemented.

How Can You Implement Regulatory Compliance In Your Business?

Like quality assurance, regulatory compliance involves using a set of standards to evaluate products and services. Thus, the first step that any company should take when implementing compliance is understanding which rules apply (and, of course, which controls and regulations they are expected to follow).

Once a company understands the rules they are expected to follow and implement, organizations must observe these rules by reporting on performance. As with quality assurance, products are judged against predetermined standards to determine if these products can be sold to customers. Thus, should these products not comply with standards, the business needs to take action.

Inspections take place to evaluate the products that will be sold to customers in a timely manner to ensure product excellence. As mentioned, should these inspection procedures conclude that the products evaluated do not reach compliance standards, changes within the production process will need to be made.

What is the Difference?

There are several differences between quality assurance and compliance. Firstly, as mentioned previously, quality management systems are intended to improve the overall design of a product and increase the efficiency of various processes and procedures at the company. Compliance, by contrast, only looks to ensure that compulsory regulatory requirements are being implemented and followed. A further difference between quality assurance and compliance is that while the latter is non-optional and mandatory, the procedures of the former (quality assurance) are implemented at the discretion of the business.

Realistically, organizations will employ both quality assurance and compliance systems – as this is the only way to ensure safety truly and constantly improve the services offered to customers. Thus, compliance can also be understood as a subset of quality assurance activities.

Quality Assurance vs. Compliance – What Do The Best Quality Management Systems Employ?

As mentioned above, assurance and compliance need to be enacted to guarantee the products’ safety and to see a continuous improvement in the products made. With this being said, companies should employ quality management systems that develop and deliver a culture of quality assurance over compliance. There are a few reasons for this. First, favoring quality over compliance reduces an organization’s overall risk. For example, organizations that only focus on ensuring compliance can see a litany of audits if the root problem is not resolved. By contrast, quality-centered organizations operate with less risk as they look to improve every stage of the production process. Moreover, quality-oriented organizations will also create innovative products in the long term; compliance-based organizations, by contrast, will never move beyond the basic quality standards required of them. As a result, customers will move away from these organizations to companies that prize product excellence and high production standards.

Wrapping Up!

Devising and implementing quality assurance and compliance at your business is easier when you support these operations with a quality management software solution. If your business requires such a solution, look no further than consulting with the NonStop Group.

The Non-Stop Group has a wealth of experience helping clients in the oil & gas, manufacturing, transportation, and logistics industries. When the NonStop Group assisted these clients, every client saw a fall in administrative work thanks to the introduction of dynamic (and audit-ready) electronic forms. Perhaps most importantly, the NonStop Group supports the cloud-sharing of data, meaning every user will have access to essential data no matter where they are. Of course, this makes gathering data needed for quality assurance easier than ever before. If you want these benefits for your company, contact the NonStop Group today.