6 Min Read

When many of us go shopping to purchase food or frequent our favorite restaurants and cafes, food safety questions are rarely our first thought. We are confident that the food we are buying and subsequently eat has been handled correctly not to cause foodborne illness.

Guaranteeing food safety for long periods is not a simple process. Controlling food safety hazards and securing food safe for consumption requires a diligent food safety management system. Every time we purchase goods from a store, their safety is a testament and reflection of these food safety management systems.

So, what exactly are food safety management systems which quietly operate in the background as we consume our food?

What is a Food Safety Management System?

A food safety management system (FSMS) is a group of procedures, practices, and principles that manage food safety, control food safety hazards, and ensure safe and high-quality food. Additionally, they conduct a hazard analysis of risk factors to all parts of the food process, which reduces these risks to an acceptable level. A food safety system is a legal requirement that businesses must implement to meet food safety regulations and ensure regulatory compliance.

However, a food safety management system is also a helpful tool that businesses can use to evaluate their current food safety measures. As a useful Tool, food safety systems assess whether a company adequately controls food safety hazards and ensures that food continues to be safe to eat.

Any food business or food industry must implement a food safety management system to mitigate foodborne hazards and ensure the continued safety of our food. Thus, small caterers, food manufacturers, large businesses, and even businesses making ready-to-eat food will have tailor-made food safety management systems with food safety management systems at every stage of the food chain—the overall level of food safety increases.

There are several methods a business can use to build a food safety management system. One such system that companies have their FSMS based on is a Hazard Analysis Critical Control Points plan (or HACCP plan.)

HACCP is an international method that ensures that food is safe to eat as it is one example of a food safety management system. This is primarily undertaken by identifying potential hazards and introducing control measures to control food safety risks and actively prevent foodborne illness.

Risk factors to food safety include chemical, physical, and microbiological threats. All three of these risk factors are accounted for and managed in any food safety system. A failure to do so can result in severe food-borne illnesses for consumers.

We will discuss the principles of the Hazard Analysis Critical Control Point shortly. But first, let’s discuss four other critical components of a food safety management system.

Imperative Components of a Food Safety Management System

Implementing a quality-safety culture:

Regulatory authorities or a food standards agency can introduce food safety regulations to ensure food safety throughout the entire food chain. However, food safety regulations are often not enough. Leadership and management Must implement a food quality-safety culture within their food safety management systems to ensure food safety.

Management can create a food quality-safety culture by taking the lead in formulating and implementing an FSMS. Additionally, management must commit visible resources to maintain food safety and ensure safe practices are always followed.

Compliance:

Complying with regulations often feels like a burden. However, as compliance is a legal requirement, not following the required rules magnifies the risk of foodborne illness and legal challenges.

Yet, regulatory compliance alone cannot be relied upon. As with creating a food quality-safety culture, a proactive approach is needed by management to ensure regulations are being followed correctly.

Traceability:

A key challenge in actively controlling food safety risks is implementing a tracking system that monitors food safety throughout the entire food chain. For example, should contaminated food be sold to a customer, a food safety management system must trace which customers have purchased the affected goods. Additionally, the contaminated goods must be traced back to the supplier of those goods.

Software tools make controlling food hazards throughout the supply chain significantly easier.

The FSMS Plan as the Foundation:

At the base of the food safety foundation is the FSMS Plan. Any food safety management system must include proper documentation which details how food hazards are handled. Additionally, employee training and training programs for food handlers are essential to keep food safe. Such training will include preventing cross-contamination, sanitizing, cooking, and refrigerating food correctly.

Food safety management systems must also include detailed and periodic audits to ensure regulations are being followed. Should corrections be implemented, management must ensure that the modifications have solved the problem.

Importance of a Food Safety Management System

Food safety procedures are essential to ensure sufficient control of the risks associated with the food process. Therefore, reducing foodborne hazards and foodborne illnesses is a central goal of any food safety management system.

Why is this important? Failure to ensure safe practices can cause a foodborne illness. Should your business be associated with unsafe procedures, customers will avoid your shop, resulting in a loss of sales and revenue. Incoming lawsuits can also follow due to a food standards agency investigation.

Therefore, prioritizing safer food practices through implementing a food safety management system is essential to maintain customer confidence in your business.

7 Principles of Hazard Analysis Critical Control Points (HACCP)

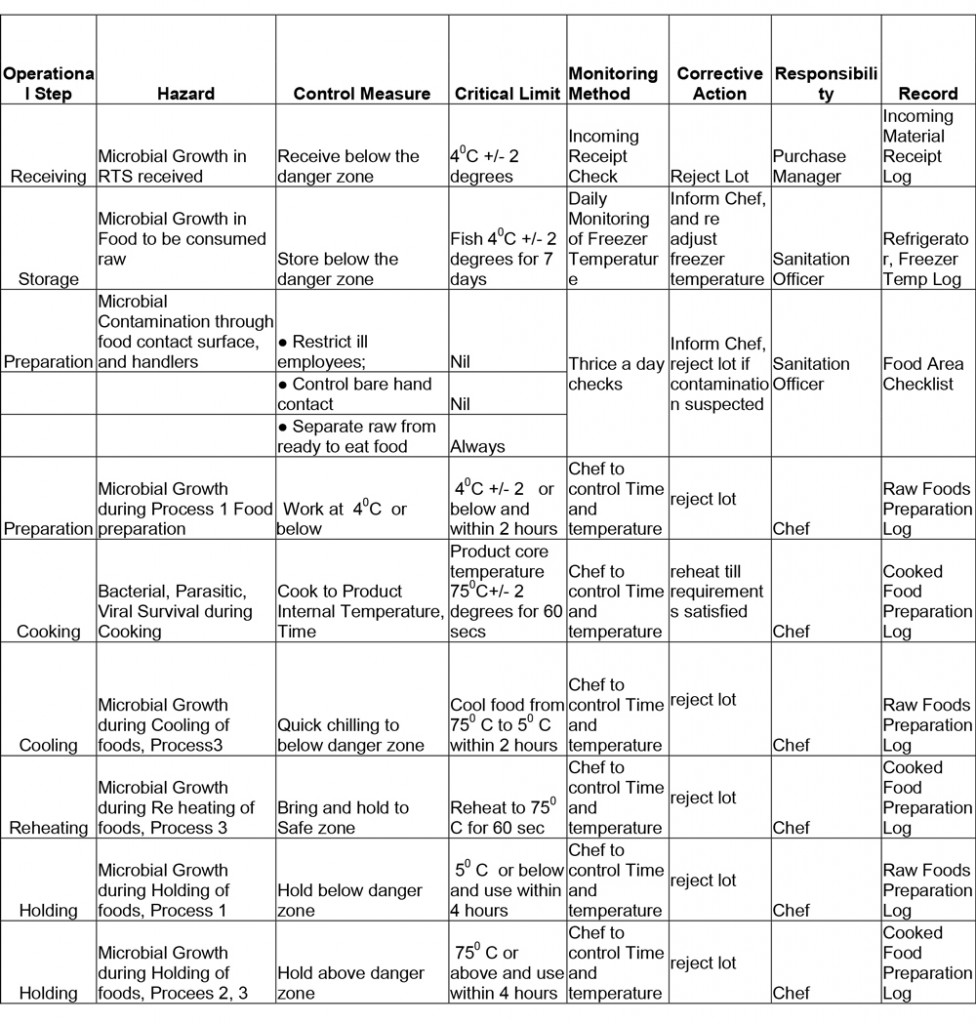

The Hazard Analysis Critical Control Point method is an international and systematic approach used to formulate food safety management systems. The core of the HACCP is actively controlling risks and controlling food safety hazards. Hazard analysis critical control involves identifying all possible dangers in the food process. After a hazard analysis is complete, rules and procedures which sufficiently control the risks identified are established.

There are seven principles to a HACCP plan. Firstly, a food business must identify all physical, chemical, and microbiological hazards in the food process. Potential risks include handling the raw food or finished products Correctly to prevent cross-contamination and ensure that food is refrigerated correctly.

Critical control points are formulated to manage each hazard after being identified. This second principle of the HACCP plan is crucial. Essential control points serve as preventative measures to reduce or eliminate risk to food safety wherever it is handled. Therefore, they include certifying that fresh ingredients are still ‘in-date’ and testing products/packaging to ensure that both are safe for consumers.

Following the formulation of crucial control points, critical limits are formed to control how the identified risks are managed. An example of a critical limit is the minimum and maximum temperature stored goods. Management will communicate these required limits to employees to guarantee continued food safety.

Following the establishment of critical limits, a business must implement practical procedures to monitor control points. For example, a company can Use a daily checklist or flowchart to detail its risk-mitigating procedures. Employees can use these checklists to verify stored goods’ expiration dates and ensure that the required critical limits are in place.

The fifth principle involves developing error-correction mechanisms. Should something go wrong in your CCP, it is crucial to create a ‘Plan B’ to implement quickly. The sixth principle is actively verifying that every step in your food safety management system is working. During this verification process, current shortcomings are identified and corrected.

Record-keeping is the final principle of a hazard analysis plan. A record-keeping system stores the details of identified hazards and the procedures to sufficiently control these hazards. Given the importance of this record-keeping system, it must be easily accessible to both management and employees.

Should all these principles be followed, the risks to food safety can be substantially reduced to consumers. However, no food safety system will be exactly alike. Thus, a small food business will have a different food management system than a large one.

Three food safety systems are available to small businesses: Safer Food, Better Business; Cook Safe Manual for Caterers; and MyHACCP. Let’s discuss each in turn.

Some Important Food Safety Management Systems

Safer Food, Better Business (SFBB)

Safer Food, Better Business is one example of a food safety management system developed for small caterers and businesses. The Safer Food, Better Business system aims to assist small businesses following food safety regulations.

Safer Food, Better Business websites have information packs on every element about food safety. These packs include information on preventing cross-contamination, proper sanitizing procedures, cooking, and chilling. Safer Food, Better business information packs, will protect a small business’s reputation, train their staff correctly, and ensure that small businesses meet regulatory requirements.

Cook Safe Manual For Caterers

Like Safe Food, Better Business, the Cook Safe Manual helps caterers implement FSMS based solutions. The FSMS solution in the Cook Safe Manual is predicated on the HACCP principles. By examining the Cook Safe Manual, caterers can build custom solutions for their businesses based on HACCP principles.

MyHACCP

Finally, the MyHACCP is a free web tool that the UK’s Food Standards Agency has developed. This tool is free to download and intended for businesses with complex food safety processes. Essentially, MyHACCP is intended to be used by food manufacturers whose business processes are more complex than smaller businesses/caterers. By contrast, smaller companies and cafes should use the tools found in the Safer Food, Better Business program.

Perks of Having a Digital Food Safety Management System

Due to the scale of a food safety management system, and the number of records that will kept, implementing a digital system to manage this data is essential. A digital food safety management system gives management and employees easy access to key documentation. This documentation includes a checklist of control points and critical limits.

A digital food safety management system also serves as a centralized location to implement corrective actions and receive reports in real-time. Additionally, a digital food safety system also enables a company to track products as they move throughout the food chain. For companies operating globally, this feature is essential to control risks throughout the entire food and supply chain actively.

How Can you Improve Your Food Safety Management System?

Reducing foodborne hazards is the central objective of food safety management systems. A simple way to improve your safety management system is to use successful HACCP templates; consulting with food safety experts is a second option. The type of experts your company requires will depend on improving your food safety system. For example, consulting with software vendors or experts is your best avenue if your company requires a digital solution.