6 Min Read

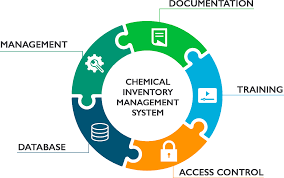

While managing hazardous materials and chemicals may sound like a simple task, nothing could be further from the truth. This is why having some form of chemical inventory management is vital. Essentially, the primary purpose of chemical inventory management is to manage and reduce risk posed by chemical and hazardous materials throughout the entire lifecycle. Among other things, chemical management involves developing a chemical inventory management system. Within this chemical inventory management system, relevant information must include chemical classification, a description of chemical structures, chemical safety information (in the form of chemical safety data sheets), and information about safe chemical storage.

There are several ways that research laboratories, research group members, and the chemical industry can support the inventory management of hazardous materials. In the past, managing the risk of chemicals, and hazards associated with chemicals, was completed with pen and paper; later, spreadsheets and legacy software systems augmented these efforts.

Today, however, chemical management is primarily completed with specialized cloud-based software called chemical inventory management software. Let’s now discuss what these software solutions can offer factories, the chemical industry, and any laboratory.

What is Chemical Inventory Software?

Primarily, chemical inventory software is used to help manage the risk associated with handling chemicals. For this reason, chemical inventory software can also be understood as ‘risk management software.’ How exactly does chemical inventory software help with chemical-based hazards? For a start, this software can track chemicals throughout the entire lifecycle – from their purchase, distribution, and eventual disposal.

A key feature of chemical inventory software is that this software enables the centralization of data/databases; in effect, a single database is created. Quick and easy access to centralized data is essential when a laboratory (or even multiple laboratories and factories across multiple locations) handles chemicals or manages their chemical inventories. One such benefit (more benefits will be discussed below) of this software is that safety data sheets can be accessed by authorized users quickly. This, in turn, increases safety for employees as they can view hazard definitions and precaution codes for chemicals, and have essential information on chemical storage and chemical disposal. Crucially, the centralization and easy-access of chemical safety information enables this information to be easily shared with emergency responders. Thus, in the event of chemical spillage or any other emergency, responders will have the necessary information on-hand.

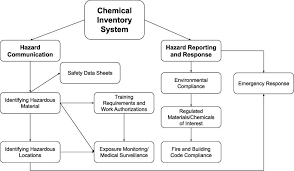

However, improving the safety of employees and consumers through the access of essential safety information is only one task chemical and risk management software. Typically, these solutions also support an entire chemical management system. Let’s discuss what is meant by a chemical management system in more detail and how cloud-based solutions help them.

Smarter Asset Tracking With NFC Tags

Learn more about how NonStop Suite's NFC Asset Tracking Solution can help your Enterprise streamline operations to new heights.

Get A Free Product Tour

Why Is a Chemical Management System (CMS) Important?

A chemical management system (or chemical inventory management system) is how organizations manage, control, and track their entire chemical inventory. A chemical inventory management system must control the many moving parts within an organization. As such, inventory management systems are concerned with all inventory transactions across an entire organization, current chemical inventory levels, and the need to establish reorder points when chemical inventory runs low. Of course, chemical management systems must consistently ensure that employee safety is assured by sharing important documentation and following safety guidelines.

However, the best chemical inventory management systems will also help an organization save costs, increase efficiency/streamlining operations, ensure regulatory compliance, and boost employee productivity. As mentioned, the best inventory systems are supported by software solutions. Essentially, the tools within these solutions help save costs, ensure compliance with regulations, and boost productivity. A discussion of chemical inventory software features will illuminate this point better.

Features of Chemical Inventory Software

Tracking of Chemical Containers

Container level tracking is a vital feature of software solutions. Working in tandem with barcode scanners and mobile apps/technology, users can search and track the location of chemicals. As all the data is available on a single database, users can track the locations of chemicals no matter where they are.

There is a critical risk-management and safety element of this feature, too. Presented alongside the location of chemical containers are manufacturer safety data sheets (such as disposal directions, the expiration date of chemicals, and chemical storage instructions); organizations can then print GHS data labels to illustrate how employees must handle the hazardous materials.

Wireless Barcode Scanning

Wireless barcode scanning is vital for tracking every stage of inventory transactions. Whether new chemicals are being received or a final product is being shipped off, barcode scanning ensures you know the location of your chemicals and the number of chemicals you possess. As most mobile devices can scan barcodes, chemicals can be scanned by management or employees from anywhere.

MRP and Forecasting

Material resource planning and forecasting are two compelling features of chemical inventory software solutions. Using past sales data/records, seasonability records, and on-hand inventory, this tool can predict upcoming material/chemical inventory requirements. Additionally, organizations can use this tool to establish purchase orders and reorder points, thereby further streamlining business operations.

With such a powerful tool, you will never need to worry about purchasing too much or too little inventory! Again, an organization saves valuable costs with this feature – not only is the risk of excess inventory eliminated, but organizations also will not need to pay additional storage costs due to no excess inventory.

Automatic Unit Conversion

While unit conversions are often the source of jokes and frustration, automatic unit conversion is another vital feature of chemical inventory solutions. Automatic conversion saves time for employees by streamlining this process; the possibility of human error is thereby also eliminated. In effect, this is helpful to save costs as the number of incorrect calculations is reduced.

Real-Time Inventory Control

Chemical inventory software solutions can provide your organization with an up to date snapshot of the chemicals in your inventory; you can also search instantly for the required chemicals with the search function. Conveniently, inventory numbers will constantly update in real-time as chemical products are bought, placed in storage, used, or disposed of. Additionally, you can also use other relevant information to assist with inventory search results, such as the CAS registry number, barcodes, or locations of the chemicals. Crucially, for real-time inventory control to become a reality at your organization, employees must ensure it remains regularly updated.

Instant Data-Integrity Checks

Again, chemical inventory solutions are critical for maintaining safety in a factory or laboratory. For example, should the wrong product or chemical be scanned during production, you will receive automatic notifications about this. Additionally, these solutions can help collect data and records for OSHA and other regulatory bodies to help ensure compliance.

Benefits of Chemical Inventory Management Software

Effortless Management

With software solutions, you can manage your chemical inventories with ease! To manage chemical storage and stocks in the past, either pen & paper or legacy systems were utilized by organizations. However, these management systems were cumbersome; and employees wasted valuable time locating chemicals and managing inventory.

With software solutions, these are now problems of the past. Manual processes and repetitive tasks can now be automated, saving time and boosting productivity. Moreover, searching for products can be done with custom fields or by location, barcode, or CAS number. When paired with mobile devices, software solutions can be used by authorized users wherever they are!

Prepare Real-Time Reports In Seconds

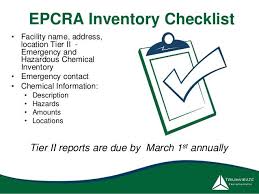

Preparing reports for either internal use or for external auditors can be completed in a matter of seconds! Reports (such as Tier II, DHS and SARA) are critical for compliance with federal regulations. However, should the required data be disorganized or decentralized, preparing for audits can take weeks. In turn, this diminishes productivity and eats into critical employee time. With chemical inventory solutions, all the relevant information is at your fingertips, meaning that you will never need to stress about audits in the future.

Eliminate the Risk of Human Error

A significant drawback in the usage of manual solutions to manage chemical inventory was the potential for human error. Whether this was double-ordering chemical products, incorrect chemical classification when inputting new information, or a miscalculation when converting units, human error increases costs for an organization. However, now that it is possible to manage your chemical inventory with software solutions, the risk of human error is significantly reduced – as the streamlining of chemical management serves as a critical correction mechanism and safety net. The prime benefit of reducing the risk of human error is reducing unnecessary waste and saving time.

Helps You Fight Regulatory Incompatibilities

Software solutions help ensure that your organization is always up-to-date with regulatory compliance requirements, both federal and international.

Wrapping Up!

Should your organization require the best solution to help manage your chemical inventory, the best place to start is to consult with the NonStopGroup. The NonStop Group has experience assisting many clients in the oil, gas, and manufacturing industries. When the NonStop Group helped these clients, they transformed their inventory management systems by introducing software solutions and mobile devices. As a result, assets/chemicals were easier to track. This resulted in employees spending more time on productive rather than repetitive tasks.

Additionally, employee safety also increased markedly due to the ease of inventory management. The NonStop Group is also fully compliant with regulations, meaning that your organization can quickly generate audit-ready reports. Should you want these results for your organization, be sure to contact the NonStop Group today!