6 Min Read

The Basics of Maintenance Digitalization

Thanks to rapid technological advances in Artificial Intelligence (AI) and Smart Manufacturing, global businesses are revolutionizing the way companies undertake their manufacturing, distribution, and maintenance tasks. New advanced technologies have helped maintenance managers digitize the maintenance process, which has made maintenance more profitable and efficient. This has helped businesses control unnecessary costs & expenses in the manufacturing process.

Maintenance digitization also provides real-time monitoring and predictive analytics to maintenance teams that allows them to utilize time for competency development, training, and executing innovative ideas.

Businesses adopting computerized maintenance management systems (CMMS) or intelligent energy meters help businesses collect electrical data, calculate health indexes in real time, and get prescriptive corrective and predictive maintenance recommendations. This allows businesses to predict machine failures or stoppages, and lower energy consumption beforehand, enabling them to avoid them by taking necessary precautions.

Corrective Vs. Predictive Maintenance

Before learning more about the key benefits and strategies of implementing maintenance digitization, it is crucial to understand the difference between corrective and predictive maintenance.

Corrective maintenance and predictive maintenance are the two approaches used in maintenance management to ensure that all machinery and machine components are functioning optimally.

Corrective maintenance is a reactive maintenance approach where maintenance activities are performed after a failure has occurred. The goal is to fix the damaged assets and restore it to normal operation. It is typically performed on an as-needed basis and can be costly since it often involves emergency equipment maintenance and repairs.

On the other hand, preventive maintenance is a proactive approach that involves monitoring equipment’s condition and predicting when maintenance should be performed before the equipment is damaged. Data analysts and on-site service technicians leverage sensor data, machine learning, and other predictive analytics to predict future failures. Comparatively, this approach is economical as the likelihood of downtime is reduced and requires a lesser upfront investment.

Smarter Asset Tracking With NFC Tags

Learn more about how NonStop Suite's NFC Asset Tracking Solution can help your Enterprise streamline operations to new heights.

Get A Free Product Tour

Benefits of Maintenance Digitization

Businesses adopting digital technologies for digitizing maintenance activities can streamline sustainable maintenance services and outcomes. Here are some of its key benefits:

Improved Data Processing and Analysis

Maintenance digitization facilitates seamless data collection, organization, and processing of Big Data, which helps maintenance teams identify trends, predict equipment failures, and reduce production costs. Digital tools provide real-time data on machine performance, allowing data scientists to analyze the collected data for better predictive maintenance and reduce the risk of unplanned downtime.

Data and Communication Security

Digital maintenance systems allow for secure and encrypted communication between maintenance teams and stakeholders, reducing the risk of data breaches & unauthorized access to sensitive information. This improves data security as digitized records are safe in case of unfortunate events such as fire, hardware failure, or theft.

Improved Inventory Management

Digital equipment data and cloud computing help manage spare parts, inventory, and supplies, reducing the risk of stockouts or excess inventory. This facilitates cost savings by optimizing inventory levels and reducing waste. Additionally, e-maintenance provide insights into the frequency of maintenance tasks, which allows for better forecasting of inventory needs and reducing the risk of unexpected maintenance costs.

Reduce Maintenance Costs

Maintenance digitization can help organizations reduce maintenance costs by enabling them to perform predictive maintenance and reduce the need for reactive maintenance. It can also help organizations optimize their use of maintenance resources and reduce the time required to perform maintenance tasks.

Better Decision Making

Digital maintenance services and insights can provide organizations with real-time data and insights about equipment performance, maintenance needs, and other key factors. Data-driven maintenance decisions can help organizations plan maintenance schedules and allocate resources optimally.

Key Considerations for Implementing Maintenance Digitization

Implementing an effective and efficient maintenance digitization system can provide numerous benefits for an organization, but there are several key considerations that must be taken into account to ensure a successful implementation. Some of these considerations include:

Develop a Clear Strategy for Maintenance Digitization

It is crucial to undertake strategic planning for the seamless digital transformation of maintenance activities. Strategic maintenance planning may include considering several outcome-based or condition-based maintenance strategies for achieving the long-term objectives of the business.

By developing a strategy based on the maintenance needs of the organization and defining how digitization can help them, businesses can ensure long-term scalability and resilience of maintenance tasks.

Secure Buy-In from Management and Key Stakeholders

Getting buy-in from management and key stakeholders is critical to the success of any digitization initiative. This involves clearly communicating the benefits of digitization and addressing any concerns they may have. Involving stakeholders in the planning process can help managers get valuable insights and ensure that their needs and expectations are met.

Build a Strong Maintenance Team

Implementing maintenance digitization requires the right mix of technical and maintenance expertise. In order to achieve better results, it is important to have the right set of people working on tasks based on their expertise, experience, and skills. This can be achieved by identifying the skills and experience required for implementing digitalized maintenance and hiring, training, and retaining personnel to fill these roles.

Prioritize the User Experience and Needs of Maintenance Personnel

Maintenance personnel are critical to the success of maintenance digitization initiatives. It is essential to understand their needs and challenges and design digitization solutions that are easy to use, intuitive, and tailored to their needs. This can help improve the user experience of the staff, increase employee productivity, build a healthy environment, and reduce the risk of resistance to change.

Focus on Data Management and Analytics for Maintenance

Data is at the heart of the maintenance digitization process, and it is essential to focus on data acquisition, management, and analytics. In order to process data seamlessly, managers must analyze the data collected, and store it effectively, to gain insights into maintenance performance. This equips maintenance staff to identify areas for improvement and take necessary actions.

Embrace Innovation and Flexibility in Maintenance Processes

Digitization provides opportunities for innovation and flexibility in maintenance processes. This involves identifying areas where digitization can bring about new approaches or improve existing ones and being open to experimentation and new ideas. A culture of innovation and flexibility can ensure that maintenance digitization initiatives are effective and more efficient in the long term.

Keep Maintenance Costs and Your Budget in Mind

Digitization initiatives can be costly. Therefore, it is essential to keep maintenance costs and budget in mind when planning and implementing digitization projects.

This involves identifying and keeping track of costs associated with digitization and developing a budget that accounts for these costs. Continuous monitoring and reviewing of maintenance costs can help managers to ensure that the project remains on track and within budget.

Framework For Maintenance Digitization

By following a conceptual framework in the age of Industry 4.0, organizations can systematically digitize their maintenance processes, optimize operations, enhance efficiency, and achieve better outcomes in terms of asset performance, cost savings, and overall maintenance effectiveness.

The proposed framework for maintenance digitization may consist of the following steps:

Preliminary Evaluation of Critical Factors:

It is essential to conduct a preliminary evaluation of critical factors, which involves assessing the current maintenance processes, identifying pain points, and understanding the potential benefits of digitization. It also includes analyzing the available resources, such as budget, infrastructure, and technology readiness.

Challenges of Digitization

Identify the challenges that may arise during the digitization process. Common challenges include resistance to change, known failure modes, lack of technical expertise, data security concerns, integration issues, and the need for cultural shifts within the organization. By identifying these challenges, you can develop strategies to address them effectively.

Initiate Digitization

After the preliminary evaluation and addressing digitization challenges, start by identifying the areas or processes that are most suitable for digitization. This can include asset management, work order tracking, preventive maintenance scheduling, inventory management, and data analysis. Prioritize working practices that offer the greatest potential for improvement and immediate impact.

Technological Deployment and Staff Training

Select appropriate digital tools, software, and technologies to support the digitization efforts. This may involve implementing a robust CMMS platform, Artificial Intelligence devices for condition monitoring, predictive analytics tools, or mobile applications for field technicians. Additionally, it is crucial to provide comprehensive training to the maintenance staff to ensure they can effectively utilize the new tools and technologies.

Develop a Maintenance Digitization Strategy

Develop a comprehensive strategy to guide the maintenance digitization efforts. This strategy should outline the goals, objectives, timelines, and key performance indicators (KPIs) for the digitization project. It should also include a roadmap for phased implementation, considering factors such as resource availability, budget constraints, and the complexity of digitizing various processes. It is important to review the strategy regularly as the digitization project progresses to ensure its alignment with organizational objectives

Final Words

Maintenance digitization has emerged as a key driver for unlocking the benefits of modern industrial processes. By leveraging digital tools, technologies, and strategies, organizations can transform their maintenance operations, optimize asset performance, and achieve significant improvements in efficiency and effectiveness.

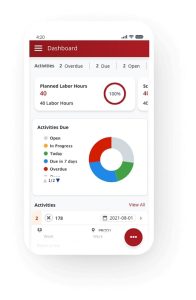

A robust CMMS application provides real-time monitoring of asset conditions, predictive maintenance capabilities, streamlined work order management, enhanced inventory control, and improved decision-making through data analytics.

The NonStop Suite (NSS) is a lightweight CMMS platform that enterprises can use to streamline maintenance-related activities. Our Suite is developed to bridge the gap between operations and maintenance by leveraging a shared dataset and digitizing the traditional forms.

Learn more!