6 Min Read

Even before the COVID-19 pandemic, a significant change was happening in the workforce. During the pandemic, we called this change ‘working from home’. Yet, before this, the number of mobile or remote workers was increasing in a number of industries.

The increasing mobility of the workforce has been partly driven by improvements in software development and the proliferation of mobile devices. These improvements came with mobile applications (or mobile apps), which further facilitated remote work.

From the perspective of enterprise asset management, the proliferation of mobile applications and devices represents a revolutionary opportunity to simplify work orders, wave goodbye to all paper-based maintenance processes, increase technicians’ productivity, and improve the overall efficiency of maintenance operations.

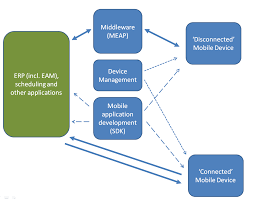

Specifically, when integrated with mobile enterprise asset management software, mobile enterprise asset management is ideal for supporting a mobilized workforce/field workers, streamlining processes and workflows, and assisting with work order management.

Before discussing the benefits of mobile enterprise asset management software, let’s first discuss what is meant by mobile Enterprise Asset Management.

What is Mobile EAM?

Mobile Enterprise Asset Management software (or mobile EAM) is generally defined as a mobile extension of existing work processes. These work processes include maintenance operations, the repair of physical assets/buildings/an organization’s facilities, and the repair of equipment. Another way to define mobile EAM is that mobile EAM is simply the addition of mobile phones and other devices to organizations’ existing EAM software.

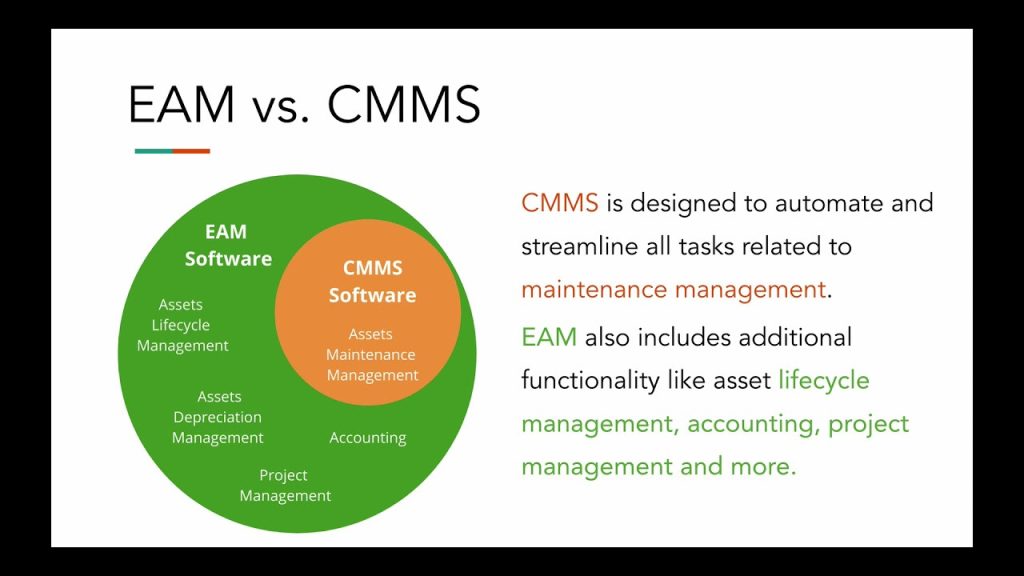

Both EAM software and mobile EAM help organizations fulfill the primary goals of enterprise asset management (EAM). However, EAM, in contrast to CMMS, focuses on the complete lifecycle of asset management. Later, we will discuss the primary differences between EAM and CMMS.

Thus, mobile EAM focuses on using a mobile device/phone to support a mobilized workforce dedicated to asset/equipment upkeep and repair. With a mobile device, technicians can access a centralized data platform on a company’s computer systems and upload/capture data to complete work orders.

Mobile EAM offers benefits for every part of a company’s workforce. For example, field technicians can access work orders in the field. Once in the field, technicians also have full access to an asset’s entire work order history and other asset information. Asset information includes additional notes, pictures, and the asset’s location.

Should technicians need additional resources during a work order, they can log these service requests while the work order is still in progress.

EAM software and an EAM system ensure complete control and visibility over asset management and work order management for planners and management. With mobile EAM, planners have access to real-time updates from field technicians about current work orders.

Additionally, with the data uploaded by technicians, management can create long-term asset management and maintenance strategies. These maintenance strategies will take the form of preventive, predictive, and condition-based maintenance. Again, due to the relevant data being on a single platform, every team member will have real-time access to it.

Smarter Asset Tracking With NFC Tags

Learn more about how NonStop Suite's NFC Asset Tracking Solution can help your Enterprise streamline operations to new heights.

Get A Free Product Tour

What Can You Expect from Mobile EAM?

When using mobile EAM software, companies and individual users can expect the following.

Seamless Order Management

Mobile EAM software, as well as mobile phones, have entirely replaced paper-based maintenance processes. Essentially, work orders are no longer generated with pen & paper/spreadsheets. Instead, a work order is now dispatched to technicians wherever they are (even in remote locations), meaning that workers avoid redundant trips to the office.

With mobile EAM, any work order can be generated, approved, closed, and amended. EAM software also means that all relevant team members will have access to any changes to the current work order.

Effortless Notification Management

Just as with work order management, EAM software and EAM mobile applications can effortlessly manage essential notifications for your office team and technicians.

With this mobile EAM feature, management can send notifications to technicians on new and updated work orders.

On the other hand, when technicians discover a new issue in the field, they can immediately send a new notification to create or update a work order. A feature like this is essential for facilitating communication across the whole company.

Schedule Your Tasks

Mobile EAM is essential to schedule tasks that are related to maintenance operations. For example, with mobile EAM, you can select when jobs and work orders must begin and assign the relevant technicians to these jobs. Conveniently, with mobile EAM, management can schedule these tasks at the press of a button.

You can also significantly streamline processes related to maintenance planning with mobile EAM. For example, checking for parts availability and assigning equipment for a work order can be completed from cellphones and other devices. Again, this eliminates the need for extensive paperwork; costs can also be lowered as technicians will no longer need to return to the office to await new work orders.

Real-time Tracking

Management can also track tasks in progress and calculate how long maintenance tasks take to complete.

Real-time tracking involves management extensively. For example, managers can introduce changes to the maintenance process using the data on how long maintenance tasks take to complete. With these changes in place, companies can lower costs further and complete maintenance tasks with greater efficiency.

Fast Reporting

Mobile EAM enables management to monitor how long maintenance tasks take to complete. Using this data, management can continuously improve maintenance processes. An improvement in how organizations perform maintenance work can benefit both technicians and customers!

Beneficial Impact on Asset Performance

Perhaps the most important benefit of mobile EAM is the impact these solutions have on the performance of an organization’s assets. For example, when technicians service assets, they can access important asset information, such as previous maintenance work; when they have completed their current task, they can add more details, too.

Additionally, with a feature such as ‘Mobile Operator Rounds’, technicians can capture sensor data from assets and equipment as they are on the move. This means that asset data and equipment data are delivered faster. It also means that management can utilize this data to plan long-term asset management operations for the organization.

EAM Vs. Mobile EAM: How is Mobile EAM Different from Traditional EAM software?

Mobile EAM is simply the mobile extension of enterprise asset management software.

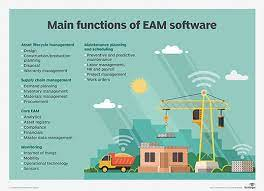

Traditional EAM software provides support to the traditional goals of enterprise asset management. Namely, these goals focus on the entire asset lifecycle – from asset procurement, asset maintenance, asset performance, and asset disposal. Essentially, EAM software facilitated these processes mentioned above.

Mobile enterprise asset management is the extension of EAM goals with the help of mobile devices. With mobile phones and tablets, technicians can access data from the EAM system (traditional EAM software is still a key feature) to help them repair facilities, equipment, and other assets.

How to Choose a Mobile Enterprise Asset Management?

When selecting mobile EAM solutions for your organization, there are several aspects that you should consider before making the final purchase.

Keep User Requirements in Mind

Firstly, always keep the operators and users of these solutions in mind. Should the operators find the purchased mobile solutions difficult or cumbersome to use, organizations will not reap the full benefits of mobile EAM. Additionally, ensure that the selected EAM solution facilitates seamless communication between operators, as this remains an essential element of mobile EAM.

Moreover, when selecting a mobile EAM solution, remember to keep in mind both the online and offline features of the solution. For example, when technicians work in remote locations with poor connectivity, online and offline components are vital for completing their work.

Make Sure the Software is Compatible with All Mobile Devices

Any purchased software solution must be compatible with the organization’s existing devices and software system. This requirement also means that your company must ensure that the data from sensors and readers can be integrated with the mobile EAM solution.

Enterprises will often purchase mobile EAM solutions from third-party vendors. As such, keep in mind that developers at these software vendors will introduce software updates, thereby potentially impacting user interface and experience.

Look for Flexibility

Finally, worthy mobile EAM solutions should enable customers to customize the interface to meet the needs of organizations. When considering the flexibility of EAM solutions, organizations must consider additional costs and the resources needed when customizing/changing the solution to fit their needs.

Additionally, the EAM solution must carry automation features that can be applied to workflows to boost technician productivity and aid the process of asset management.

CMMS Vs EAM: How is EAM Different From CMMS?

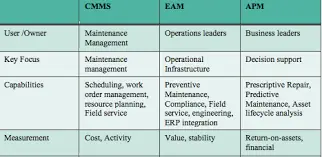

Earlier, we mentioned that the differences between EAM and a computerized maintenance management system (CMMS) would be discussed. The main difference between the two is one of scope – where EAM holistically focuses on the entire asset lifecycle, CMMS mainly focuses on how to maintain assets so that they last longer.

While both EAM and CMMS are solutions used to maintain physical assets, equipment, and an organization’s facilities, the application of CMMS is narrower than that of EAM. As mentioned, CMMS is solely used by operators maintaining assets. On the other hand, EAM is used by maintenance operators, finance teams, compliance teams, and the production team.

Of course, there is some overlap between CMMS and EAM. For example, both strategies track the performance of their assets over time to increase uptime; additionally, both approaches utilize the data recorded from their maintenance efforts to improve further their equipment’s performance and the services provided to their clients.

Wrapping Up!

How can your business introduce a mobile EAM solution into your workplace? No matter the industry your company is a part of, you should consider consulting with the NonStop Group as soon as possible.

Consult with the NonStop Group: The NonStop Group has a wealth of experience helping clients implement mobile EAM solutions for their enterprises. With a mobile EAM solution introduced, your company can wave goodbye to paper forms! Instead, all your data will be stored on a centralized cloud platform, thereby significantly streamlining the management of work orders.

The NonStop Group’s mobile EAM solution is also in full compliance with FDA 21 CFR Part 11 regulations.

If you want to manage your assets with ease, contact the NonStop Group today!