6 Min Read

Almost all enterprises rely on certain physical assets and equipment, which play a significant role in the success of a business. Therefore, businesses need to ensure that the assets are in good operating condition.

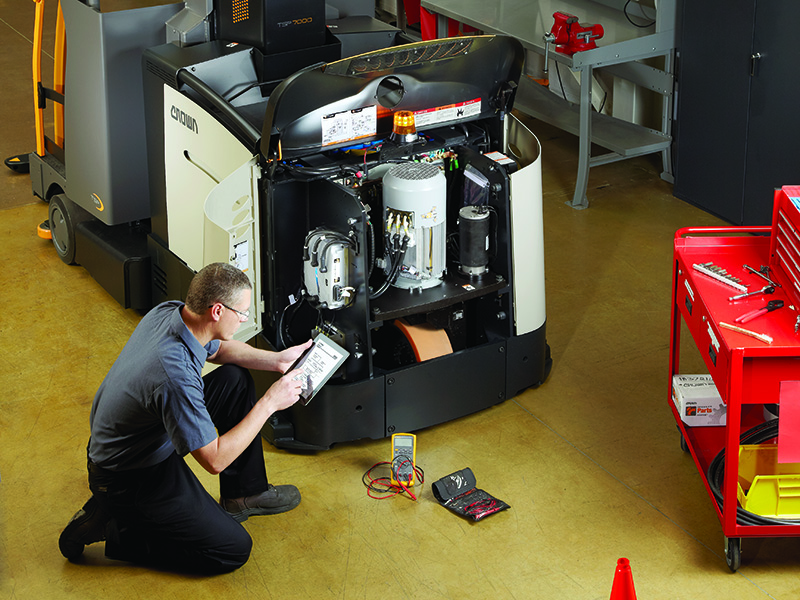

This is where preventive maintenance inspection comes into play – asset maintenance & visual inspections of physical equipment help you detect potential hazards & asset breakdowns in advance, preventing expensive repairs and ensuring all business operations run uninterrupted.

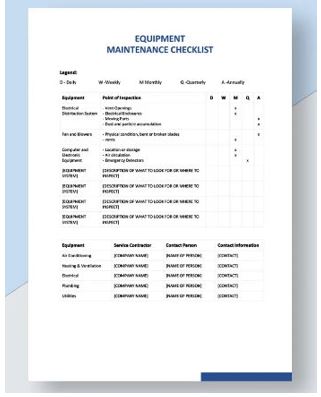

An asset maintenance checklist is an effective logbook that technicians use to document asset maintenance inspections. Maintenance checklists cover all important aspects relating to the life of an asset and ensure that no detail is left uncovered.

This guide will cover more details on preventive maintenance checklists and ways to maximize the benefits of an effective maintenance checklist. Continue reading to learn more

Perks of A Good Maintenance Inspection Checklist

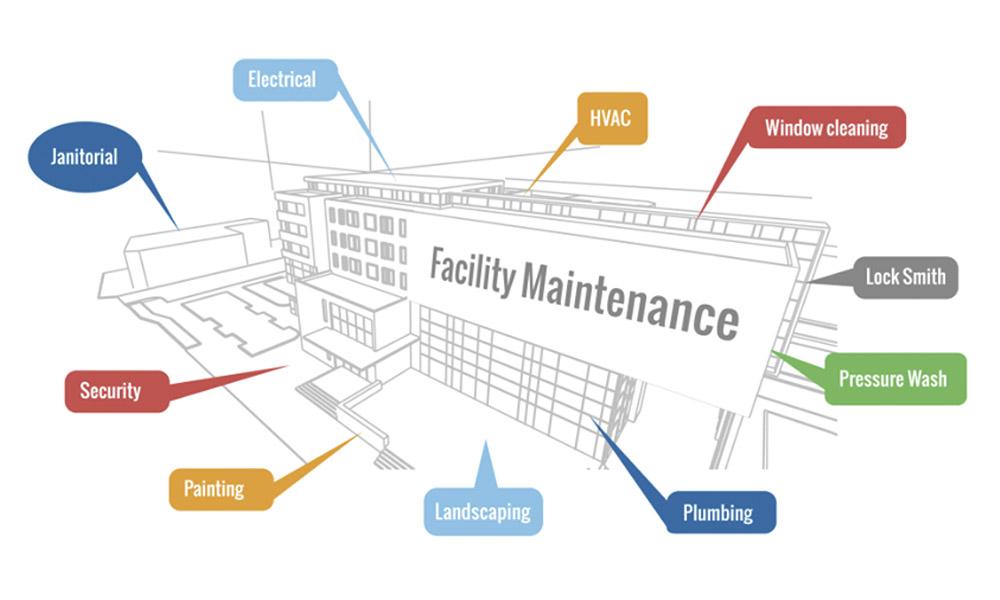

An effective maintenance inspection checklist can help facility owners consistently ensure regular maintenance or upgradation of equipment and the entire facility. The maintenance checklist provides that technicians follow a predefined set of instructions & guidelines to carry out facility maintenance operations like replacing air filters, replacing fire extinguishers, upgrading fire alarm systems, fixing water leaks, and repairing air conditioning systems.

Other key benefits of a robust maintenance inspection checklist are as follows.

Quick Asset Inspections & Building Maintenance

An all-inclusive preventive maintenance checklist ensures that all assets and equipment provide operational excellence at all times. Checklists define the roles and responsibilities of the maintenance technicians, allowing them to execute their functions quickly.

Additionally, it also enables new and inexperienced technicians to work independently, speeding up asset maintenance inspections.

Minimized Human Errors

A well-curated preventive maintenance checklist can prevent equipment failure due to a lack of skill, slip-ups, or momentaneous lapses. A robust preventive maintenance program includes instructions like safety hazards and cautionary signs for inspection technicians that minimizes the chance of injury.

Furthermore, inspection checklists help managers identify the technician in charge in case of any damage to equipment.

Workflow Standardization and Increased Productivity of Assets

Outlining steps and procedures for a technician result in increased productivity of assets with minimal supervision. It also standardizes maintenance work that carries on for a long duration.

For example, suppose one technician is working on water damage treatment in the gutters. In that case, checklists make it easy for other technicians to resume work and ensure that the gutter water is draining properly at any point & time

Smarter Asset Tracking With NFC Tags

Learn more about how NonStop Suite's NFC Asset Tracking Solution can help your Enterprise streamline operations to new heights.

Get A Free Product Tour

How to Check the Effectiveness of an Inspection Checklist?

Once a predictive maintenance checklist is prepared and used, maintenance managers must comprehend the results and benefits of the performance of assets and equipment. Ideally, an effective checklist must deliver the following results:

- Technicians take lesser time for maintenance inspections.

- Maintenance technicians work independently without much supervision and external guidance.

- During maintenance inspections, technicians perform operations more consistently.

- Lowered equipment downtime and enhanced asset productivity.

- The increased average lifespan of assets in the long run.

- Seamless, proper operation of work orders that involve assets & equipment.

Basic Elements of an Inspection Checklist

In order to create and maximize the use of effective & robust inspection checklists, it is important to consider crucial information and factors that play a central role in any preventive maintenance program.

Identifying and Understanding the State of Assets and Equipment

Managers and maintenance technicians should take note of the performance, uptime, efficiency, quality, and maintenance cost of the asset. It is also vital to understand important aspects of assets frequently require preventive maintenance.

Collecting Documentation

Every asset & machine comes with certain instructions or usage guidelines provided by the manufacturer. It is important to gather these specs and information to help maintenance technicians prepare inspection checklists

Creating Custom Reports & Documents

In preparing the inspection checklists, managers must document comprehensive processes and preventive maintenance plans. This report can be easily reviewed and accessed by technicians and can be used to prepare future maintenance checklists

How to Make an Efficient Maintenance Inspection Checklist?

During routine maintenance of the facility, technicians should observe patterns that may signal the need for periodic part replacements and maintenance tasks. These observations can help managers make an efficient inspection checklist.

The following steps can also help managers make a structured inspection checklist.

Effectively Plan a Preventive Maintenance Checklist

It is crucial to consider the current and potential usage & condition of an asset when making an inspection for the checklist.

Managers must plan and schedule regular condition-based assessments of the following elements:

- Condition of assets, workhouse, and equipment

- The functioning of machine guards that ensure human safety

- Presence of visible warning signs and instructions.

Automating Predictive Maintenance Checklists with a Robust CMMS

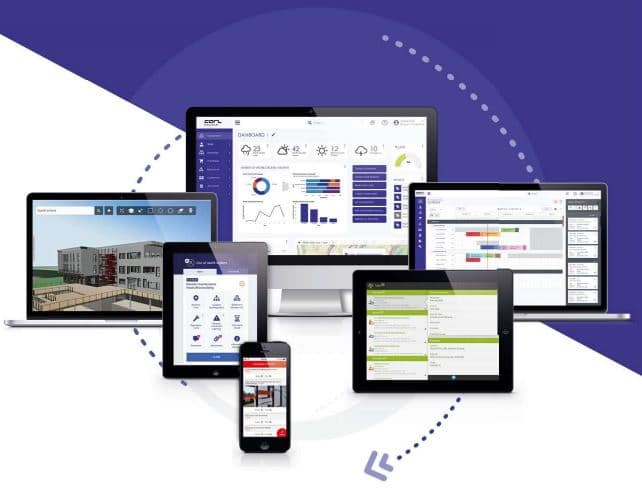

To enhance efficiency, inspection checklists can be made with dynamic electronic forms built into a powerful Computerized Maintenance Management Software (CMMS).

Electronic forms built into a robust CMMS like the NonStop Suite can help you save time and improve your inspection workflows

Integrate Checklists with Operational Workflows & Processes

Different facilities have different workflows and processes. Preventive maintenance checklists should be implemented with these workflows in order to document long-term approaches and maintenance insights. Moreover, to ensure the privacy of processes, managers should make checklists available only to specific technicians.

Review Feedback and Accordingly Act on Checklists

It is important to derive feedback from assets and equipment on implementing the checklists. The feedback must be put into action by altering the checklists to prevent costly repairs of the assets or immediate shutdown.

Some Preventive Maintenance Checklist Templates for Proper Operation

For Safety

- Ensure a passable distance between assets and equipment.

- Ensure that all safety controls and measures are being followed.

- Ensure all debris and harmful materials are properly disposed of.

- Inspect and upgrade the fire alarm system, fire extinguishers, etc.

- Examine contaminant zones and areas regularly to maintain good condition of the facility.

- Examine smoke detectors & fire extinguishers in all parts of the facility.

For HVAC

- Replace air filters and ensure optimum air filter standards regularly.

- Regular inspections of all electrical connections of the air conditioning system.

- Proper Installation of HVAC ductwork.

- Install carbon monoxide detectors in the HVAC system.

For Plumbing

- Clean drains and identify signs of water damage & leaks.

- Regularly inspect gutters and network of pipes.

- Schedule damage inspection of faucet aerators and water pressure assets.

- Observe storm drains.

- Maintaining and plumbing bad faucets and fixtures.

For Facility Infrastructure

- Check for mold growth and pest infestation in different facility areas like parking lots, lawns, and the building roof.

- Schedule interior checks of the facility twice a year.

- Schedule replacement or repairs of broken windows, broken glass, and damaged light switches in all facility spaces.

- Maintaining sufficient interior and exterior lighting to ensure the good condition of the facility.

- Inspect CCTV cameras in the parking lot, warehouse, and factory floor.

- Regularly remove trash and ensure cleanliness in the entire facility, especially areas such as the roof, parking lot, kitchen, pantry, and restrooms.

- Schedule petty repairs like fixing knobs of the doors, welding iron rods, and polishing wooden doors.

For Network and Data Systems

- Schedule and perform data backups regularly.

- Organizing network cables and device inventory.

- Fixing minor problems relating to hardware dusting and system maintenance.

- Regularly inspect malware protection and network documentation updates.

- Establishing reliable network security to prevent data leaks.

- Performing HDD checks and running diagnostic tools.

For Material Handling Equipment

- Ensure inventory and equipment are fully stocked.

- Ensure optimum oil levels in engines and vehicles.

- Put inspection tags once the inspection of assets is complete.

Lubricate bearings and other spare parts of the machinery.

Digitize Your Checklists With CMMS For Maximal Benefits

Digitizing maintenance checklists with a robust CMMS can help maintenance managers in accessing checklists anytime and at any place, allowing technicians to validate and check tasks remotely. All business documents are gathered and stored at a centralized cloud platform, which prevents data loss and provides real-time feedback to other technicians and business managers.

CMMS solutions enable managers and technicians to access checklists on mobile devices to carry out maintenance tasks, develop compliance reports, and establish maintenance standards. For a better understanding of the inspection process for new and inexperienced technicians, CMMS solutions also allow senior technicians to add images and other media files to the checklists.

Robust CMMS solutions like The NonStop Suite are developed to bridge the gap between operations and maintenance by leveraging a shared dataset and digitizing the traditional forms that make cross-department visibility impossible.

Wrapping Up!

Maintaining business assets and equipment is one of the most crucial aspects of a business, and maintenance inspection checklists can help managers ensure effective and optimal facility maintenance. Preventive maintenance inspection involves the identification of damaged or worn-out components and replacing or repairing them before the asset fails. It helps businesses extend the service life of the equipment and reduces production downtime.

Modern-day businesses integrate powerful solutions like CMMS solutions, NFC tags, and electronic forms to prepare and implement inspection checklists. These robust technologies give businesses the added advantage of executing their inspection activities effectively and quickly.

If you are looking for robust CMMS applications, try The NonStop Suite