6 Min Read

As tools, equipment, and vehicles move from place to place and between different departments, tracking these assets is vital for various reasons. However, keeping track of your fixed and mobile assets can be a challenging process.

Businesses can use various asset tags to track assets, such as barcode labels, Radio Frequency Identification (RFID tags), QR codes, and Global Positioning System (GPS) trackers. These asset tags need to be supported by business processes, technology processes, and software solutions. This brings us to the importance of AMS.

What is Asset Management Software (AMS) and How Does it Work?

At its core, businesses use AMS to track assets throughout their entire lifecycle – from the moment of procurement until the assets are disposed of. But, more importantly, with AMS, businesses gain additional data from their assets. With this other data and information, companies can make better decisions about maintaining their assets.

When a business has better visibility over its assets, it can save costs over the long term. For example, better-maintained assets will see fewer breakdowns, meaning additional charges do not arise due to asset downtime.

Data security is an essential feature of AMS systems, too. For example, businesses can restrict account sign-in and sign-out to selected users. Additionally, software vendors continuously update their servers to ensure even better data security.

While AMS is an essential dimension of contemporary business processes, AMS must complement other items and tools such as asset tags.

Smarter Asset Tracking With NFC Tags

Learn more about how NonStop Suite's NFC Asset Tracking Solution can help your Enterprise streamline operations to new heights.

Get A Free Product Tour

What is an Asset Tag?

An asset tag consists of a printed label that is attached to assets. There are multiple reasons why businesses use asset tagging labels. As mentioned, these labels consist of barcode labels, QR codes, RFID tags, and GPS tags.

Firstly, each label is a unique identification number that distinguishes the asset from other company assets.

Secondly, an asset tag is much more than just a label. Maintenance operations become far more manageable if a sound AMS system supports these tagged assets, saving time and costs. In addition, when physical assets’ labels are scanned, important asset information about previous maintenance services is displayed.

Additionally, with GPS tracking, it is possible to know the location of your vehicles, valuable equipment, and essential tools needed for maintenance operations. As tools and even inventory can be quickly moved between departments, knowing where your assets are in this mobile environment brings some order to business processes.

Thus, the relationship between asset tags/labels and the AMS system works both ways. Without asset labels, tracking asset movements and asset locations is impossible, but no meaning can be given to these tags without an AMS system.

Why Do You Need Asset Tags?

We have already covered a few reasons why asset tags and labels are essential for businesses. We can now cover a few more.

Theft Prevention

Unfortunately, asset theft remains a significant problem for businesses that results in billions in additional costs per year. Compounding this problem is that assets go missing, resulting in additional costs to replace them.

With asset tags, your company knows where its critical assets are at all times. This is particularly helpful for items that are prone to theft. Over the long term, this can save companies additional expenses.

Real-time Asset Tracking system

You need a system that supports this mobility for assets on the go. Searching for vehicles, tools, equipment, and inventory can be time-consuming. Using asset tags such as RFID tags and GPS trackers can instantly locate valuable equipment.

Of course, not every asset or piece of equipment will require an asset tag or label. Before placing a tag or label on their assets and purchases, companies must consider a few factors. Generally, the assets and equipment given asset tags are deemed essential for revenue generation, are expensive to replace, or will cause critical damage/loss should they fail.

While this does not provide real-time tracking, tagging computers, and other office equipment can assist purchasing decisions. Businesses can even give furniture an asset tag. Attaching an asset tag to your furniture and office equipment during a move can be helpful.

Additionally, equipment such as spare parts or even a power tool should be tagged, too. Not only does this help with theft prevention, tracking these assets as they move between departments saves time and resources.

Save Time and Resources

When it comes to locating equipment for maintenance work, this can be a time-consuming process should your assets not have tags to identify them. Wasting time locating equipment can be frustrating and consume valuable company resources. However, with asset tags and labels, businesses can quickly find equipment currently in use and its present location.

Thus, as equipment needed for maintenance moves from location to location and between departments, your asset tags will ensure they are tracked for the entire process.

Not only are asset labels convenient for equipment needed for maintenance, but retailers also save time and resources by tracking their inventory with RFID tags or barcode labels. Additionally, barcode labels also provide excellent data on current inventory levels, so employees cannot manually check inventory levels.

Process of Asset Tagging

Businesses cannot simply begin tagging their assets at will. Instead, there is a process of tagging that companies must follow before attaching the final tag onto their assets.

Assign Identification Number

The asset tagging process begins by first creating asset types/asset categories. Once an asset category has been made, unique identification numbers are assigned to these assets. Importantly, these serial numbers must be unique for management and employees to recognize and identify the assets.

Using unique identity numbers is essential for helping management identify the total number of assets; this also helps establish re-ordering points and allows for accounting purposes.

Choose a Tag/Label

After creating an asset category and a unique identification number to identify assets, companies must select the correct tag for their assets. How does one go about choosing the right tag? When selecting a label, a few factors must be considered – including environmental factors and asset type.

For assets that must be tracked in real-time, such as cars, trucks, cranes, and planes, a GPS tag would work best. However, barcode labels and QR codes are the best choices for businesses that need to count inventory and track packages over a short distance. An RFID tag is also suitable for tracking assets in real-time; as an RFID tag can be scanned and read at longer distances, they are also ideal for difficult-to-reach assets.

Essentially, each asset tag has its benefits and drawbacks, meaning that companies must select asset tags effectively to ensure maximum benefit. It is up to individual businesses to decide how asset tracking can be accomplished with the available tags.

Create Asset Profile

When the asset tag is created, be sure to gather and record additional information about the asset before attaching the tag to begin asset tracking. The information you record should include the Model, serial number, date of purchase, the asset’s location, value, condition, and expected duration.

This asset information should be accessible to workers and management through an asset tagging system. Additionally, such information is essential for tracking expected costs and asset investment in the future.

Affix Tags

With your asset tag and profile created, you can tag your assets. Once the assets have been tagged, asset tracking can begin.

Types of Asset Tags

We have already discussed that the type of asset tag companies can use depend on environmental conditions and the type of asset which needs tracking.

We can now discuss three such tags available for asset tracking: RFID, QR Codes, and GPS trackers. We will also discuss the enduring importance of barcode labels, especially for companies with large amounts of inventory and storage operations.

RFID

Radio Frequency Identification (RFID) tags have been used since World War II. Since the 2000s, their popularity has grown as more commercial retailers have used them to track assets.

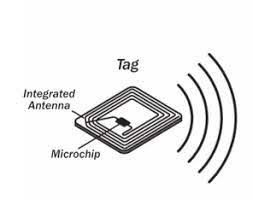

RFID tags work as follows: radio signals emanating from a passive or active tag attached to an asset; when an RFID reader device captures these radio signals, the tag will provide data to the reader. Depending on the asset, this data could include an inventory number, model number, or even a record of previous maintenance operations. As RFID tags do not require direct scan access, they are beneficial for hard-to-reach assets.

QR Code

Since their commercial introduction, QR codes and barcode labels have been attractive asset tracking solutions, especially for businesses with large amounts of inventory on the move and in storage units. To be scanned, barcode labels require a scanner device or mobile device.

The proliferation of mobile devices means that QR codes are an attractive label as they can be scanned with one. Additionally, QR code labels and barcode labels help track a limited or quick order due to the ease of scanning. A short order includes postal or mail deliveries.

GPS Trackers

Global Positioning System (GPS) trackers work with satellites to provide real-time tracking of assets. While GPS trackers are not suitable for indoor assets, they are beneficial for fleet management, logistics, and transportation. Moreover, heavy-duty vehicles such as cranes, vans, or trucks can also be equipped with GPS trackers to track their location as they move from site to site.

Wrapping Up!

While asset tags form an integral part of asset management, their effectiveness is only as good as the asset management software (AMS) that supports them. NonStop Suite can help with asset tags and introduce asset management solutions and management technology for your business.