5 Min Read

Overview Of Maintenance Planning And Scheduling

Proper maintenance planning and scheduling can lead to a significant increase in productivity. Below we offer tips on how to improve your maintenance planning and scheduling strategy.

Maintenance planning and scheduling are at the core of an effective maintenance management system, yet they are, perhaps, the most neglected tasks in modern asset management. By making sure to implement a CMMS like IBM Maximo, all preventive maintenance planning and scheduling tasks become more manageable. The overall planning, scheduling, and control activities to ensure that planned work is carried out correctly can now have the ability to run at optimal levels.

A lot of asset-intensive organizations recognize the importance of effective maintenance planning and scheduling for equipment reliability and achieving operational excellence. However, studies have shown that most of these companies still do not have an effective maintenance planning and scheduling strategy in place. This is an interesting fact since maintenance planning and scheduling strategy are key to an effective maintenance management system.

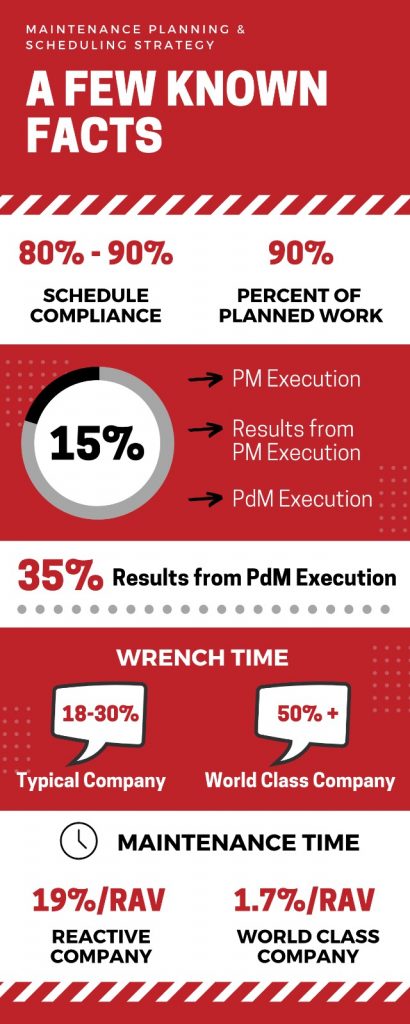

Typically, a lack of effective maintenance planning and scheduling leads to a negative impact on work effectiveness, equipment uptime, wrench time, equipment reliability, and cost.

For peace of mind and to reduce downtime to the barest minimum, organizations will have to adopt structured, carefully managed, and effective maintenance planning and scheduling processes.

Facts On The Impact Of Efficient Maintenance Planning & Scheduling For Organizations

What Are The Steps Of The Maintenance Planning Process?

There Are Five Actionable Maintenance Planning Steps

The whole idea of a maintenance planning process is to identify the correct maintenance jobs and integrate them into the scheduling process. To achieve this, a selected planner designs a work plan or job plan for each planned work. A work plan details everything a technician has to do to carry out a task.

1. Shield The Planner

Make sure planners are taken out of the maintenance crews. This protects the planning function and always allow planners to fully focus on maintenance planning for future purposes.

2. Focus On Future Work

The main purpose of this step is to give the maintenance department a week’s worth of planned work that is ready for execution.

3. Let Planners Determine Time Estimates

Ideally, planners should be selected from among the best technicians in the organization. Make sure to leave a reasonable time to estimate tasks to allow a technician to complete a work order without problems.

4. Take Different Skill Sets Into Consideration When Planning

Planners need to know their craft technicians’ skills when creating job plans. Planners will determine the scope of the work order and overall strategy for the work, which would include a procedure to determine skill level. Once the technicians complete the task, they can work with the planner on other jobs thereby making checklists and procedures better.

5. Adopt Work Sampling For Performance Evaluation

This principle classifies wrench time as the primary mode of evaluation for workforce efficiency as well as for the effectiveness of the planning and scheduling process. Wrench time means technicians can work whenever they need to without delays resulting from having to wait for an assignment or spare parts, travel time, getting clearance, & co. Planned work reduces needless delays during jobs and scheduling work decreases delays in between jobs.

Five Maintenance Scheduling Steps To Implement

About Maintenance Scheduling

It’s possible to have a great planning department working to come up with work plans and planning procedures, but it doesn’t always mean an improvement in the amount of work done. If a job that formerly took four hours to finish now takes two hours, it still only means one job has been completed. Essentially, planning makes it easy to complete individual projects while scheduling helps boost productivity.

1. Job Plans Are Necessary For Scheduling:

A job plan should have the necessary information, such as the number of technicians needed, work hours, skill levels, and job duration. Maintenance requires this information to schedule work; therefore, asking the necessary questions during the design of a job plan helps with scheduling.

2. Schedules And Job Priorities Are Essential:

The weekly schedule and its most important considerations are vital to enhancing productivity. Making advanced scheduling a priority helps ensure that adequate workloads are assigned, thereby boosting productivity and ensuring that critical work orders are finished first.

3. Schedule Based On The Estimated Highest Skill Set Available:

A scheduler should design a one-week schedule for every crew dependent on the highest skills available, available technician hours, job priorities, and job plan details.

4. The Crew Leader Should Handle Daily Work:

A daily schedule derived from the current job progress, a one-week schedule, and any latest high-priority jobs, should be developed by the supervisor or crew leader. Daily work should be assigned to technicians based on the work order requirements and their skill level.

5. Adopt Schedule Compliance For Performance Evaluation:

Scheduling success can be assessed by the level of compliance with the one-week schedule and how effective it has been. Wrench time is the best measure of workforce efficiency as well as the effectiveness of planning and scheduling. When work is carefully planned before it is assigned, delays between jobs are drastically reduced.