6 Min Read

In the fast-paced landscape of modern business, the effective management of assets, equipment, and maintenance processes is paramount to ensuring operational efficiency and sustainability. This is where Computerized Maintenance Management Systems (CMMS) emerge as indispensable tools for organizations across various industries.

A maintenance management software streamlines maintenance operations, enhances asset performance, and contributes to overall cost-effectiveness. Conversely, the absence of computerized maintenance software can have profound implications for businesses, ranging from increased downtime, unexpected breakdowns, and rising operational costs to potential safety risks.

What is a Computerized Maintenance Management System (CMMS)?

A Computerized Maintenance Management System is designed to streamline and optimize the management of an organization’s maintenance activities. CMMS serves as a centralized hub that facilitates the planning, tracking, and execution of maintenance tasks for all types of assets, from machinery and equipment to facilities and vehicles. The system enables facility managers and maintenance teams to schedule preventive maintenance, manage work orders, track inventory levels, and generate insightful reports.

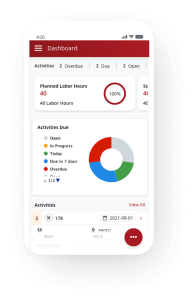

By leveraging a user-friendly interface, a CMMS system empowers users at various organizational levels to access real-time data, fostering better decision-making and enhancing overall operational efficiency. With its ability to automate routine maintenance processes, track asset performance, and minimize downtime, a well-implemented CMMS becomes a cornerstone for proactive maintenance management, ensuring that resources are utilized optimally and the organization operates at peak performance.

Smarter Asset Tracking With NFC Tags

Learn more about how NonStop Suite's NFC Asset Tracking Solution can help your Enterprise streamline operations to new heights.

Get A Free Product Tour

Who Needs A CMMS Solution?

Determining who needs Computerized Maintenance Management Software involves recognizing the diverse range of industries and organizations that can benefit from its functionalities. Primarily, any business or institution that relies on assets, equipment, or facilities to conduct its operations can find value in implementing a CMMS solution.

Small to large enterprises may also need a CMMS, as it can help them meet the unique needs of different organizational sizes. Maintenance managers, facility supervisors, and operations teams can leverage the insights provided by a CMMS for tracking labor hours, repairing equipment, scheduling tasks, allocating human resources efficiently, and making informed decisions. Moreover, organizations that are expected to meet regulatory compliances can use CMMS to track and document maintenance activities, ensuring adherence to regulatory standards.

In essence, anyone seeking to enhance their maintenance processes, reduce downtime, extend asset lifespan, and improve overall operational efficiency stands to gain from implementing a CMMS solution. As we delve into the signs indicating the need for a CMMS, businesses across diverse sectors will find valuable insights tailored to their specific operational challenges.

What Organizations Benefit From CMMS?

Various industries benefit significantly from implementing Computerized Maintenance Management Systems (CMMS), particularly businesses seeking to enhance their maintenance processes and overall operational efficiency.

- Manufacturing Companies: In the manufacturing industry, where uptime and equipment reliability are critical, CMMS plays a pivotal role in ensuring smooth operations. Manufacturers utilize CMMS to schedule preventive maintenance, track equipment performance, and manage work orders efficiently. This leads to increased productivity, improved equipment effectiveness, and reduced asset downtime.

- Facilities Management: Facilities management spans a wide range of environments, from office buildings to educational institutions. Maintenance management software assists facility managers in maintaining various assets, such as HVAC systems, lighting, and security equipment. Furthermore, facilities can streamline maintenance workflows, extend the lifespan of equipment, reduce equipment downtime, and enhance the comfort and safety of occupants with preventive maintenance software tools.

- Hospitality Sector: CMMS helps hotels and resorts manage maintenance tasks for rooms, common areas, and amenities. This ensures a positive guest experience by preventing unexpected breakdowns and addressing issues proactively. Additionally, computerized maintenance tools help hospitality businesses record labor hours, prepare a maintenance budget, and forecast maintenance issues, which increases staff responsiveness and overall work efficiency.

- Transportation Companies: Transportation companies rely heavily on a well-maintained fleet and infrastructure. CMMS software aids in tracking and managing the maintenance of assets. This ensures standardized processes and compliance with safety standards, minimizes downtime and extends the lifespan of transportation assets.

- Energy Sector: The energy sector, encompassing utilities, power plants, and renewable energy facilities, benefits from CMMS in maintaining complex and critical infrastructure. CMMS helps manage the maintenance of generators, turbines, and other equipment, contributing to optimal operational efficiency, reducing downtime, and ensuring compliance with regulatory standards.

10 Signs Your Company Needs a CMMS

Recognizing signs within your organization underscores the need for a robust CMMS solution, presenting an opportunity to enhance operational efficiency, reduce costs, and ensure the longevity of your assets. Below are some signs indicating the need for a CMMS.

Increased Downtime and Unplanned Maintenance

Frequent breakdowns and increased downtime can be a glaring sign that your company needs a CMMS. The system helps identify patterns of equipment failures, enabling the maintenance team to take proactive measures to reduce unplanned downtime and maintain consistent productivity.

Inefficient Work Order Management

If your company struggles with tracking, prioritizing, and managing work orders effectively, a computerized work order system can streamline the process. CMMS provides a single platform for creating, assigning, and tracking work orders, ensuring timely completion and improved communication among maintenance teams.

Inadequate Asset Tracking

The inability to accurately track and manage assets can lead to asset inefficiencies and increased maintenance costs of assets. CMMS offers a robust asset tracking system, allowing organizations to monitor the performance, maintenance work histories, and location of each asset in real time.

Absence of Proactive Maintenance Strategy

Without a proactive maintenance strategy, organizations often end up reacting to issues as they arise. A CMMS enables the implementation of preventive maintenance schedules, reducing the likelihood of unexpected breakdowns and extending the lifespan of assets.

Poor Inventory Management

Inventory mismanagement can result in overstocking or critical inventory levels, leading to increased costs. CMMS solutions include features for enhanced inventory management, ensuring that the right parts are available when needed, minimizing downtime, and controlling costs.

Compliance and Regulatory Challenges

If your business is struggling to meet compliance and regulatory standards, it is highly suggested to invest in a CMMS software. Industries with strict regulatory requirements can benefit from a CMMS’s ability to document and track maintenance activities. This can help ensure compliance with industry standards and regulations, reducing the risk of fines and penalties.

Challenges in Making Data-driven Decisions

In the absence of reliable data, decision-making becomes challenging. CMMS provides detailed insights into maintenance performance, allowing organizations to make informed, data-driven decisions to optimize processes and resource allocation.

Lack of a Preventive Maintenance Program

A reactive maintenance approach can be costly and disruptive. A CMMS facilitates the implementation of preventive maintenance programs, helping organizations anticipate and address issues before they escalate, ultimately saving time and resources.

Communication Gaps Among Maintenance Teams

Ineffective communication may lead to incorrect decisions and hinder an organization’s objective to achieve its goals. A CMMS enhances communication by providing a centralized platform where teams can collaborate, share information, and stay updated on work orders and asset status.

Scalability Challenges

As your company grows, managing maintenance activities manually becomes increasingly challenging. CMMS solutions are scalable, adapting to the evolving needs and size of your organization, ensuring continued effectiveness in managing maintenance processes.

How Do I Choose a CMMS?

Choosing the right CMMS is a critical decision that significantly impacts the effectiveness of your maintenance operations. To ensure that you select a CMMS that aligns with your organization’s needs, consider the following key factors:

- User-Friendly Interface: Look for a CMMS with an intuitive and user-friendly interface. This ensures that your maintenance team can navigate the system without extensive training, promoting seamless integration into your workflow.

- Scalability: Consider implementing computerized maintenance software that can scale with your organization’s growth and should be preferred over others. It must accommodate an increasing number of assets, users, and locations, which ensures long-term viability and adaptability to evolving business requirements.

- Mobile Accessibility: Opt for a CMMS that offers mobile accessibility. This allows maintenance teams to access and update information on the go, streamlining communication and improving response times to critical issues.

- Integration Capabilities: Ensure that the CMMS can integrate seamlessly with other existing software and systems within your organization, such as ERP systems or asset management software. Integration enhances data accuracy and reduces duplication of efforts.

- Reporting and Analytics: Comprehensive and accurate reporting and analytics tools are essential for gaining insights into maintenance performance. Choose a CMMS that provides detailed reports, key performance indicators (KPIs), and analytics to support data-driven decision-making.

6. Preventive Maintenance Features: Prioritize a CMMS that facilitates preventive maintenance planning. The system should allow the maintenance department to schedule and automate routine maintenance tasks, helping to prevent unexpected breakdowns and extend asset lifespan.

7. Cloud-Based vs. On-Premises: Evaluate whether a cloud-based or on-premises CMMS is better suited to your organization. Cloud-based solutions offer flexibility and accessibility, while on-premises solutions provide greater control over data security. Choose based on your organization’s preferences and infrastructure.

The NonStop Suite: The Ultimate CMMS for Your Organization Needs

The adoption of Computerized Maintenance Management Systems stands as a strategic imperative for companies looking to elevate their maintenance operations, enhance efficiency, and ensure the longevity of their assets. The ten signs discussed serve as crucial indicators, guiding businesses toward recognizing when the time is ripe for a CMMS implementation. From mitigating downtime and improving work order management to addressing compliance challenges and fostering data-driven decision-making, a CMMS proves instrumental in overcoming these obstacles.

Introducing the NonStop Suite – the ultimate Computerized Maintenance Management System (CMMS), your organization needs to revolutionize its maintenance operations. Designed with a user-centric approach, the NonStop Suite offers a set of comprehensive solutions that address the diverse needs of companies ranging from manufacturing and facilities management to hospitality, transportation, and energy.

Are you looking to invest in a CMMS system? Make the shift to NonStop Suite and transform your maintenance operations into a proactive, efficient, and streamlined process.